Conclusion

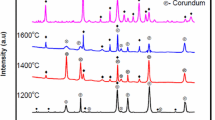

It is shown that the temperature of initial crystallization of glass spheres of mullite composition with diameters of less than 0.1 mm, in the metastable state, equals 935°C. The phase composition of the spheres of diameters from 0.1 to 0.5 mm varies. With an increase in the diameter of the spheres from 0.5 to 1–1.7 mm their properties vary slightly.

Thermal processing of the spheres of mullite composition with different starting contents of mullite and glass in the mullite component influences the crystallization of the mullite and causes increases in the density at temperatures from 900–1300°C. The most rapid change in properties takes place in the spheres containing the maximum amount of glass phase (100%). In the 1300–1500°C range in all spheres, with different contents of glass phase in the starting condition, there is a variation in the density and in the mass proportion of mullite.

An increase in soaking from 0.5 to 1.5 h at 1300 and 1500°C leads to an increase in the mullite content and a rise in the density of the glass spheres.

During the firing of finely milled powders made of granules and spheres with different contents of glass phase and mullite, and also specimens prepared from these powders, with temperature rise the material's density and the amount of mullite are both increased, and the changes in these factors are identical. It is established that with increase in the mullite concentration in specimens of finely milled powders there are marked reductions in shrinkage, and apparent density; and an increase in the porosity of the specimens fired at 1750°c. There is much less change in the properties at 1700°c.

Similar content being viewed by others

Literature cited

N. V. Pitak, V. S. Shapovalov, V. A. Ustichenko, et al., Production of Special Refractories [in Russian], MChM SSSR, Metallurgiya, Moscow (1979) No. 7, pp. 25–32.

N. V. Pitak, V. S. Shapovalov, et al., Use of Refractory Materials in Technology [in Russian], Reports from the 2nd All-Union Conference, Leningrad (1976), pp. 129–130.

V. A. Ustichenko, V. V. Primachenko, et al., Physicochemical Processes in the Production and Use of Refractories [in Russian], MChM SSSR, Metallurgiya, Moscow (1981), p. 16–20.

I. Fiala and Ya. Fialova, R. Zh. Khimiya, No. 7, 11 (1980).

V. A. Ustichenko, N. V. Pitak, and A. A. Korovinskaya, Ogneupory, No. 11, 14–18 (1986).

L. A. Korobka, V.-S. Shapovalov, and V. A. Ustichenko, Ogneupory, No. 12, 44–47 (1978).

R. McPherson, J. Am. Ceram. Soc.,63, Nos. 1–2, 110–112 (1980).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 4, pp. 7–10, April, 1990.

Rights and permissions

About this article

Cite this article

Ustichenko, V.A., Pitak, N.V. & Korovyanskaya, A.A. Influence of heat treatment of fused mullite materials on their properties. Refractories 31, 197–201 (1990). https://doi.org/10.1007/BF01282365

Issue Date:

DOI: https://doi.org/10.1007/BF01282365