Conclusions

An investigation of the rheological and technological properties of titanium dioxide slips and slip castings demonstrated the presence of two castability regions. The properties of the slip and castings are optimal in the alkaline castability region (pH 8).

A study of the influence of the firing temperature of the titanium dioxide starting material on the properties of the slip and castings showed that the properties are optimal when the TiO2 had been fired at 1550° C.

An analysis of the sintering of titanium dioxide slip castings showed that the properties of the sintered castings are optimal when the castings were produced from slip with pH 8 because in this case the density of the castings is at maximum.

The strength of TiO2 castings in the sintering process depends on their porosity and that of the sintered castings on the size of the crystals.

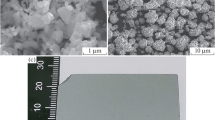

Titanium dioxide fired at 1550°C yielded castings with open porosity 1.8–2.0%, apparent density 3.90–3.92 g/cm3, σb 1020–1050 kgf/cm2, acid resistance 97.5%, specific inductive capacitance 90–100, and tangent of the dielectric loss angle at 20°C and 1 MHz 8·10−4–9·10−4

Similar content being viewed by others

Literature cited

A. S. Berezhnoi, Ogneupory, No. 11, 493–504 (1950).

V. Yu. Kramnik and I. E. Dudavskii, in: Titanium and its Alloys [in Russian], No. 6, Izd. Akad. Nauk SSSR, Moscow (1961), pp. 260–264.

É. Bonshtedt, Perovskite. Minerals of the Union, Ser. A [in Russian], No. 6, Izd. Akad. Nauk SSSR, Moscow-Leningrad (1935).

K. Simenov, Ber. Dtsch. Keram. Ges.,40, No. 7, 422–423 (1963).

G. P. Kalliga, Casting of Zirconia Refractory Products [in Russian], Metallurgiya, Moscow (1964).

G. V. Kukolev and A. G. Karaulov, Ogneupory, No. 4, 168–174 (1963).

I. S. Kainarskii, A. G. Karaulov, and G. E. Gnatyuk, Kolloidn. Zh.,29, No. 6, 810–814 (1967).

I. S. Kainarskii, Processes in Refractories Technology [in Russian], Metallurgiya, Moscow (1969).

Author information

Authors and Affiliations

Additional information

Translated from Ogneupory, No. 3, pp. 28–33, March, 1978.

Rights and permissions

About this article

Cite this article

Verba, L.I., Degtyareva, É.V. Rheological and technological properties of titanium dioxide slips and the properties of the castings. Refractories 19, 158–163 (1978). https://doi.org/10.1007/BF01280470

Issue Date:

DOI: https://doi.org/10.1007/BF01280470