Abstract

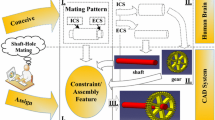

In the integration of design and manufacturing, one of the primary techniques is to evaluate the parts in the assembly so that the labour cost can be reduced. In this paper, the mechanical parts within the design and assembly are examined, and an integrated architecture of an assembly model is proposed which includes a proper assembly environment, the interface between the assembly model and feature-based design, and a knowledge-based expert system for assembly analysis. In order to determine satisfactory plans for assembly and to achieve the required functions in the product model, explicit relational information between the major components is implemented. The evaluation of interference checking of the parts and the geometric tolerances (such as perpendicularity, parallelism, and angularity) of the parts in the assembly model are also studied.

Similar content being viewed by others

References

L. I. Lieberman and M. A. Wesley, “AUTOPASS: an automatic programming system for computer-controlled mechanical assembly”,IBM Journal of Research and Development,21, pp. 321–333, 1977.

L. I. Lieberman, M. A. Wesley and D. D. Grossman, “A geometric modeling system for automated mechanical assembly”,IBM Journal of Research and Development,24(1), pp. 64–74, 1980.

C. M. Eastman and M. Henrion, “Guide: a language for design information system”,Computer Graphics,11(2), 1977.

C. M. Eastman, “The design of assemblies”,SAE Technical Paper Series, Society of Automotive Engineerings, USA, 1981.

K. Lee and D. Gossard, “A hierarchical data structure for representing assemblies: part 1”,Computer Aided Design,17, pp. 20–24, 1985.

K. Lee and D. N. Rocheleau, “System for interactive assembly modelling”,Computer Aided Design,19(2), pp. 65–72, March 1987.

G. Boothroyd and P. Dewhurst,Product Design for Manufacture, Boothroyd Dewhurst Inc., 1989.

S. Miyakawa and T. Ohashi, “The Hitachi assemblability evaluation method”,Proceedings of the International Conference on Product Design for Assembly, Newport, RI, April, pp. 1–13, 1986.

B. L. Miles and K. G. Swift, “Working together”,Manufacturing Breakthrough, p. 69, March/April, 1992.

G. Angermuller and K. Moritzen, “A knowledge-based system supporting product design for mechanical assembly”,1st Conference on Artificial and Expert Systems in Manufacturing, p. 181, March 1990.

L. M. Rosario and W. A. Knight, “Design for assembly: extraction of geometric features from a CAD system data base”,Annals of the CIRP,38(1), pp. 13–16, 1989.

R. K. Li and C. L. Huang, “Assembly code generation from a feature-based geometric model”,International Journal of Production Research,30(3), pp. 627–646, 1992.

E. Molloy, H. Yang and J. Browne, “Design for assembly within concurrent engineering”,Annals of the CIRP,40, pp. 107–110, 1991.

E. Molloy, H. Yang and J. Browne, “Feature-based modelling in design for assembly”,International Journal of Computer Integrated Manufacturing,6(1,2), pp. 119–125, 1993.

T. L. De Fazio and A. C. Edsall, “A prototype of feature-based design for assembly”,Journal of Mechanical Design,115, pp. 723–734, 1993.

J. K. Gui and M. Mäntylä, “Functional understanding of assembly modelling”,Computer Aided Design,26(6), pp. 435–451, 1994.

C. F. You and S. Y. Wang, “An approach to object-oriented feature-based CAD system”,Proceedings of the Tenth National Conference of the Chinese Society of Mechanical Engineers, Hsinchiu, Taiwan, pp. 241–250, 1993.

K. Lee and G. Andrews, “Inference of the positions of components in an assembly”,Computer Aided Design,17(1), pp. 20–24, 1985.

Y. S. Cheng, “Knowledge-based generative process planning in feature-based design”, MS thesis, National Taiwan University, Taiwan, ROC, 1994.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

You, CF., Chiu, CC. An automated assembly environment in feature-based design. Int J Adv Manuf Technol 12, 280–287 (1996). https://doi.org/10.1007/BF01239615

Issue Date:

DOI: https://doi.org/10.1007/BF01239615