Abstract

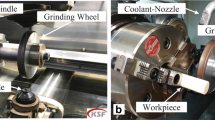

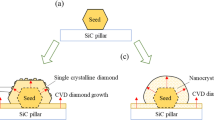

Fine ceramics have the properties of high hardness, chemical inertness, high thermal resistance and low electrical conductivity, but, because of high hardness and brittleness, they are very difficult to machine. Therefore, a superabrasive diamond wheel is used for mirror-like grinding of this material. In this study, an in-process electrolytic dressing system for carrying out mirror-like surface grinding was constructed. Using this system the grinding force for fine ceramics was reduced. This work shows that the application of electrolytic dressing is beneficial in obtaining a mirror-like surface when grinding fine ceramics.

Similar content being viewed by others

References

K. Kitajima, G. Q. Cai, N. Kumagai and H. W. Zheng, “Study on mechanism of ceramics grinding”,Annals of the CIRP,41, pp. 367–371, 1992.

H. Ohmori, “Elid mirror surface grinding technology with electrolytic in-process dressing”,Elid Grinding Research Group, pp. 8–31, 1991.

Editor of MFL. “The trend and future of mirror like grinding”,Material Fabrication Laboratory, pp. 147–148, 1991.

R. Komanduri and W. R. Reed, “A new technique of dressing and conditioning resin bonded superabrasive grinding wheel”,Annals of the CIRP,29, pp. 239–243, 1980.

J. D. Kim and E. S. Lee, “Crack generation and the effect of inprocess electro-discharge dressing in grinding single crystal MGO”,International Journal of Mechanical Sciences, 39, pp. 569–583, 1995.

H. Ohmori and T. Nakagawa, “Mirror surface grinding on silicon wafers with electrolytic in-process dressing”,Annals of the CIRP,39, pp. 329–332, 1990.

J. D. Kim, “New concept according to the compensation of dressing gap for optimum in-process electrolytic dressing”,International Conference on Precision Surface Finishing and Burr Technology, Seoul, pp. 349–366, 1994.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kim, JD., Lee, ES. A study of mirror-like grinding of fine ceramics with in-process electrolytic dressing. Int J Adv Manuf Technol 12, 246–254 (1996). https://doi.org/10.1007/BF01239611

Issue Date:

DOI: https://doi.org/10.1007/BF01239611