Summary

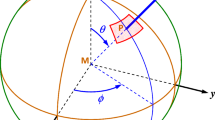

It has been attempted here to model the mechanical response of granular media through a combination of analytical, numerical and experimental techniques. Based on the experimental evidence obtained from a series of triaxial laboratory experiments on specimens made of glass beads, the model attempts to simulate the movement of yield surfaces and the stress-strain relationships. It is found that the yield surface distorts in the direction of loading in a manner analogous to that of metals. An anisotropic distortional yield model is formulated in order to describe the experimental behavior exhibited by these granular media. From the experimental yield surfaces the parameters of the model have been evaluated and a hardening rule, based on the Phillips rule, has been determined. Associativity on the π-plane has been observed experimentally. Using these concepts the constitutive formulation has been presented and the stress-strain curves have been generated. From the comparisons of these curves we observe a good correlation between the model and the experimental observations.

Similar content being viewed by others

References

DiMaggio, F. L., Sandler, I. S.: Material models for granular soils. J. Eng. Mech.97, 935–950 (1971).

Dobry, R., Ladd, R., Yokel, F. Y., Chung, R. M., Powell, D.: Prediction of pore water pressure buildup and liquefaction of sands during earthquakes by the cyclic strain method. Building Sci. Ser. 138, National Bureau Standards 1982.

Helling, D. E., Miller, A. K., Stout, M. G.: An experimental investigation of the yield loci of 1100-0 aluminium 70∶30 brass and an overaged 2024 aluminium alloy after various prestrains. J. Eng. Mat. Techn.108, 313–320 (1986).

Jenkins, J. T.: Volume change in small strain axisymmetric deformations of a granular material. In: Micromechanics of granular materials (Satake, Jenkins, J. T., eds.). Amsterdam: Elsevier 1988.

Johnson, K. L.: Contact mechanics. Cambridge: Cambridge University Press 1985.

Klisinski, M., Sture, S., Runesson, K., Ko, H. K.: Incremental constitutive law for cohesionless granular materials based on fuzzy sets. In: Proceedings 7th ASCE-EMD Speciality Conference (Heller, R. A., Shing, M. P., eds.), pp. 50. Blacksburg, Virginia 1988.

Mindlin, R. D., Deresiecwicz, H.: Elastic spheres in contact under varying oblique forces. ASME J. Appl. Mech. Trans.20, 327–344 (1953).

Petrakis, E., Dobry, R.: Micromechanical modelling of granular soils at small strains by arrays of elastic spheres. Report CE-87-02, Rensselear Polytechnic Institute, Troy 1987.

Petrakis, E., Dobry, R.: Micromechanical behavior and modeling of granular soils. Report to US AFOSR, Rensselear Polytechnic Institute, Troy 1989.

Petrakis, E., Dobry, R., Ng, T. T.: A study of the behavior and micromechanical modelling of granular soil. Volume III: A numerical investigation of the behavior of granular media under load. Report AFOSR-89-0350, Rensselear Polytechnic Institute, Troy 1991.

Petrakis, E., Dobry, R., Van Laak, R., Kotsanopoulos, P.: A study of the behavior and micromechanical modelling of granular soils. Volume II: Report AFOSR-89-0350, Rensselear Polytechnic Institute, Troy 1991.

Phillips, A.: Yield surfaces of pure aluminium at elevated temperatures. In: IUTAM Symposium on Thermo-Inelasticity (Bolgy, B., ed.), pp. 241–258 Berlin: Springer 1968.

Phillips, A., Weng, G. J.: An analytical study of an experimentally verified hardening law. J. Appl. Mech.42, 375–378 (1975).

Stout, M. G., Martin, P. L., Helling, D. E., Canova, G. R.: Multiaxial yield behavior of 1100 aluminium following various magnitudes of prestrain. Int. J. Plasticity1, 163–174 (1985).

Voyiadjis, G. Z., Foroozesh, M.: Anisotropic distortional yield model. ASME J. Appl. Mech.57, 537–547 (1990).

Voyiadjis, G. Z., Thiagarajan, G., Petrakis, E.: Anisotropic distortional yield model for granular media. In: Microstructural characterization in constitutive modelling of metals and granular media (Voyiadjis, G. Z., ed.), pp. 119–134. ASME-MD32, 1992.

Petrakis, E., Van Laak, R.: An experimental verification of the behavior of granular media. In: Mechanics of granular materials and powder systems (Mehrabadi, M., ed.) pp. 93–106. ASME-MD37, 1992.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Voyiadjis, G.Z., Thiagarajan, G. & Petrakis, E. Constitutive modelling for granular media using an anisotropic distortional yield model. Acta Mechanica 110, 151–171 (1995). https://doi.org/10.1007/BF01215422

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01215422