Abstract

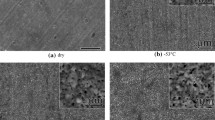

The nonisothermal oxidation behavior of 0.16% carbon steel at a heating rate of 7 K·min−1 up to a temperature of 1400 K in dry air (\(P_{O_2 }\)=21.27 kPa) is reported. It was envisaged to develop a cheaper and easily applicable superficial coating material for minimization of scale loss during high-temperature exposure. The coating material consisted of an aqueous slurry of bentonite and calcium silicide mixture. Such a coating material when applied superficially on the steel surface not only enhances oxidation resistance but also helps in forming an adherent oxide scale to the alloy substrate even up to a third cycle of exposure to 1400 K. Postoxidation analyses of the alloy-scale combination using XRD, SEM, and EDS revealed the formation of a barrier layer comprised of complex silicates and aluminoferrite that provided improved oxidation resistance.

Similar content being viewed by others

References

H. J. Engell and K. Bohnenkamp,First International Congress on Metalic Corrosion (Butterworths, London, 1961), p. 215.

G. J. Billing, W. W. Smeltzer, and J. S. Kirkaldy,J. Electrochem. Soc. 117, 111 (1970).

W. E. Boggs and R. H. Kachik,J. Electrochem. Soc. 116, 424 (1969).

W. E. Boggs, inHigh Temperature Gas-Metal Reaction in Mixed Environments, S. A. Jansson and Z. A. Foroulis, eds., (Met. Soc. AIME, 1972), p. 84.

G. B. Gibbs,Oxid. Met. 7, 173 (1973).

G. B. Gibbs, M. R. Wootton, W. R. Price, and K. E. Hodgson,Oxid. Met. 7, 183 (1973).

S. E. Khalafalla and S. L. Payne,Oxid. Met. 7, 201 (1973).

E. Nosek and T. Werber,Oxid. Met. 25, 121 (1986).

D. Caplan, G. I. Sproule, R. J. Hussey, and M. J. Graham,Oxid. Met. 12, 67 (1978).

C. A. Siebert,Trans. Amer. Soc. Metals. 27, 752 (1939).

C. W. Tuck, M. Odgers, and K. Sachs,Corros. Sci. 9, 271 (1969).

R. B. Runk and H. J. Kim,Oxid. Met. 2, 285, 307 (1970).

A. L. Cabrera, Z. E. Zehner, and J. N. Armor,Oxid. Met. 36, 265 (1991).

S. K. Roy, A. Auddya, and S. K. Bose,React. Solids 6, 30 (1989).

S. K. Mitra, S. K. Roy, and S. K. Bose,Oxid. Met. 34, 101 (1990);37, 95 (1992).

R. A. Kumar, B. Tech. thesis, Department of Metallurgical Engineering, I.I.T., Kharagpur, India (1992).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kuiry, S.C., Roy, S.K. & Bose, S.K. A superficial coating to improve high-temperature-oxidation resistance of a plain-carbon steel under nonisothermal conditions. Oxid Met 41, 65–79 (1994). https://doi.org/10.1007/BF01196643

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01196643