Abstract

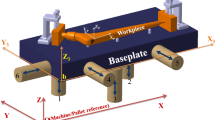

Fixturing locating point synthesis considers the workpiece and the fixturing elements to be rigid, but however they are elastic and deformable. To ensure sustained quality of manufacture to meet the design tolerances, fixture design must be predictably repeatable. This paper is concerned with minimizing deformation of the workpiece due to machining loads about fixturing support positions, especially in thin castings. Finite element analysis is used in simulating the deformation of the workpiece at selected points. An optimization algorithm is developed to minimize deflections at these selected nodal points by considering the support and tool localtions as design variables. The resulting support locations and tool point designs ensure part support, kinematic closure and minimal workpiece deflections during machining.

Similar content being viewed by others

References

Cai, W.; Hu; S.J.; Yuan, J.X. 1996: Deformable sheet metal fixturing: principles, algorithms, and simulations.J. Manufacturing Sci. Engrg. 118, 318–324

DeMeter, E. 1996: The development of meta-models for the analysis and design optimization of machining fixtures.Manufacturing Rev.

Hockenberger, M.J.; DeMeter, E.C. 1995: Effect of machining fixture design parameters on workpiece displacement.Manufacturing Rev. 8, 22–32

Kashyap, S. 1997:An integrated methodology for fixture design, analysis, and optimization Ph.D. Thesis, Rensselaer Polytechnic Institute, Troy, NY

Kashyap, S.; DeVries, W.R. 1997: Kinematic constraint of workpiece during machining: A feature-based approach.Trans. NAMRI/SME, pp. 141–146

Kashyap, S.; DeVries, W.R. 1998: A concurrent engineering framework for manufacturability evaluation, fixture design, analysis, and optimization in virtual prototyping.Proc. 31-st CIRP Conf. in Manufacturing Systems, pp. 517–522

Lee, J.; Haynes, L. 1987: Finite-element analysis of flexible fixturing system.J. Engrg. Ind., Trans. ASME 109, 134–139

McNeal-Schwendler Corporation 1995:Patran FEM modeling, customization, and analysis users guide

Menassa, R.; DeVries, W. 1991: Optimization methods applied to selecting support positions in fixture design.J. Engrg. Ind. 113, 412–418

Press, W.H.; Teukolsky, S.A.; Vellerling, W.T.; Flannery, B.P. 1992:NUMERICAL RECIPES in C the art of scientific computing, 2nd edition. Cambridge University Press

Reklaitis, G.V.; Ravidran, A.; Ragsdell, K.M. 1983:Engineering optimization methods and applications. Wiley-Eastern Publication

Vanderplaats, G.N. 1990:Numerical optimization techniques for engineering design: with applications. McGraw Hill Series in Mechanical Engineering

Author information

Authors and Affiliations

Additional information

Communicated by J. Sobieski

Rights and permissions

About this article

Cite this article

Kashyap, S., DeVries, W.R. Finite element analysis and optimization in fixture design. Structural Optimization 18, 193–201 (1999). https://doi.org/10.1007/BF01195994

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01195994