Abstract

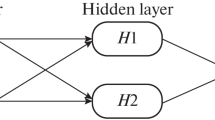

The purpose of tolerance allocation is to find a combination of tolerances to individual components such that the assembly tolerance constraint is met with minimum production cost. There are several methods available to allocate or apportion the assembly tolerance to individual parts. Some of the most common methods use linear programming, Lagrange multipliers, exhaustive search and statistical distributions. However, all the methods have some limitations. Moreover, most of these methods cannot account for the frequently observed mean shift phenomena that occur owing to tool wear, chatter, bad coolant, etc. This paper presents a neural networks-based approach for the tolerance allocation problem considering machines' capabilities, and mean shifts. The network is trained using the backpropagation learning method and used to predict individual part tolerances.

Similar content being viewed by others

References

W. H. Greenwood and K. W. Chase, “A new tolerance analysis method for designers and manufacturers”,Transactions of the ASME 109, pp. 112–116, 1987.

O. Bjorke,Computer-Aided Tolerancing, ASME Press, New York, 1989.

M. F. Spotts, “Allocation of tolerances to minimize cost of assembly”,ASME publication: 72-WA/DE-6, pp. 1–3, 1973.

W. Michael and J. N. Siddal, “The optimization problem with optimal tolerance assignment and full acceptance”,ASME publication: 80-DET-47, pp. 1–9, 1981.

J. Peters, “Tolerancing the components of an assembly for minimum cost”,Journal of Engineering for Industry, pp. 677–682, 1970.

D. Wilde, “Simplifying discrete tolerance assignment”,ASME publication: 75-DET-106, pp. 1–7, 1975.

K. W. Chase and W. H. Greenwood, “Design issues in mechanical tolerance analysis”,Manufacturing Review 1(1), pp. 50–59, 1988.

H. E. Trucks,Designing for Economical Production Society of Manufacturing Engineering, Dearborn, Michigan, 1987.

J. M. Zurada,Introduction to Artificial Neural Systems. West Publishing Company, New York, 1992.

T. Kohonen, “An introduction to neural computing”, in P. Mehra and B. Wah (ed.),Artificial Neural Networks: Concepts and Theory, pp. 32–45, 1992.

R. H. Cabell, E. A. Scott, A. B. Cook, C. R. Fuller and W. F. O'Brien, “An overview of neural network research in the VPI&SU-NASA acoustics and vibration research program”,Proceedings of the Second Workshop on Neural Networks, Academic/Industrial/NASA/Defense, pp. 231–239, 1991.

R. P. Lippmann, “An introduction to computing with neural nets”,IEEE ASSP Magazine, pp. 4–22, April 1987.

R. P. Lippmann, “Pattern classification using neural networks”,IEEE communications Magazine, pp. 47–64, November 1989.

D. R. Hush and B. G. Horne, “Progress in supervised neural networks: what's new since Lippmann”,IEEE Signal Processing Magazine, pp. 8–39, January 1993.

A. C. Tsoi, “ANN modelling of a steel rolling plate mill”,Proceedings of the Second International Neural Networks Conference, pp. 699–705, 1991.

J. M. Twomey, A. E. Smith and M. S. Redfern, “A neural network model of the dynamic coefficient of friction”,Proceedings of 2nd Industrial Engineering Research Conference, pp. 187–191, May 1993.

D. D. Bedworth, M. R. Henderson and P. M. Wolfe,Computer Integrated Design and Manufacturing, McGraw Hill, New York, 332 pp., 1991.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kopardekar, P., Anand, S. Tolerance allocation using neural networks. Int J Adv Manuf Technol 10, 269–276 (1995). https://doi.org/10.1007/BF01186878

Issue Date:

DOI: https://doi.org/10.1007/BF01186878