Abstract

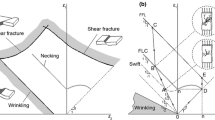

Fully plastic structures are desirable to help detect impending failure. For stability, the displacement per unit drop in load due to any crack growth must be less than the compliance of the surrounding structure. The corresponding crack growth ductility is less with asymmetric configurations, than with the symmetric ones usually studied. Examples are given of face-grooved plates with unequal flank angles, staggered cracks, and single cracks near welds in joints under tension or bending. Further examples are the tendency of cracks on a microscopic scale to become rough, to zig-zag, or even to spiral (in round bars).

The maximum triaxiality can occur on a single slip line between staggered cracks from opposing faces of a plate, according to a slip line analysis. Except at the lowest triaxiality, 1018CF steel with a 3 mm ligament became unstable even when the compliances of the surroundings totalled only 6 × 10−6 mm/N. For higher triaxialities the limit load was not reached and the ensuing unstable fractures usually turned to cleavage.

In plates, the slow,stahle, plastic extension of slant-mode through-cracks sometimes abruptly changed to cleavage fracture, even at 10°Cabove both the 0.51 mm lateral expansion and Charpy 34.1 J (25 ft-Ib) transition temperatures, either sufficient to meet the ASME Code. In structures, this means that fragmentationcan intervene even during slow, “low-triaxiality”, stable crack growth in material meeting Code requirements.

Résumé

Des constructions à caractéristiques totalement plastiques sont souhaitables pour permettre la détection de risques de rupture. Pour conserver la stabilité, il faut que le déplacement par unité de chute de la charge associée à toute croissance d'une fissure soit inférieur à la compliance avoisinante de la construction. La ductilité vis-à-vis de la croissance de la fissure est plus faible en configurations asymétriques que dans les configurations symétriques généralement utilisées dans les études.

Des exemples de plaques comportant des entailles de surface à angles de bordes inégaux, de fissures en quinconce et de fissures simples au voisinage de joints soudés soumis à traction ou à flexion sont fournis. D'autres exemples montrent à l'échelle microscopique la tendance pour les fissures à devenir grossières, à zigzaguer ou même à se spiraler (dans des barreaux ronds).

Conformént à une analyse des lignes de glissements, a la triaxialité maximum peut survenir sur une ligne simple de glissement entre des fissures en quinconce partant de la face opposée d'une plaque. A l'exception du cas de triaxialité la plus faible, l'acier 1018 CF avec un ligament de 3 mm devient instable même lorsque les compliances de la structure avoisinante ne totalisent ue 6.10−6 mm/N. Pour des triaxialités plus importantes, la charge limite n'a pas été atteinte, et les ruptures instables qui résultent se muent généralement en clivages.

Dans les tôles, on a constaté que l'extension lente, stable et plastique de fissures traversantes obliques peut soudain se muer en rupture fragile, même à 10°C au dessus de la température correspondant à une expansion latérale de 0.51 mm, ou au-dessus de la température de transition Charpy V correspondant à 25 ft-lb, ces deux critères étant pourtant conformes au code ASME.

Dans les constructions, ceci signifie qu'une fragmentation peut survenir même au cours d'une croissance lente, stable et “en faible triaxialité” d'une fissure dans un matériau qui satisfait aux prescriptions du code.

Similar content being viewed by others

References

F.A. McClintock and A.S. Argon (eds.),Mechanical Behavior of Materials, Addison-Wesley, Reading (1966) 378.

F.A. McClintock, inFracture, Vol. 3, H. Liebowitz (ed.), Academic Press, New York (1971) 155–162.

A.P. Green,Journal of the Mechanics and Physics of Solids 2 (1954) 197–211.

F.A. McClintock,Welding Journal Research Supplement 26 (1961) 202–208.

G.A. Kardomateas and F.A. McClintock,International Journal of Fracture 35 (1987) 103–124.

J.W. Carson, “A Study of Plane Strain Ductile Fracture”, Ph.D. thesis, Department of Mechanical Engineering, Massachusetts Institute of Technology, Cambridge (1970). See also [7].

F.A. McClintock and J.L. Bassani, inThree-Dimensional Constitutive Relations and Ductile Fracture, S. Nemat-Nasser (ed.), North Holland (1981) 123–145.

J. Miklowitz,Journal of Applied Mechanics 17 (1950) 159–168.

C.F. Tipper,Metallurgia 39 (1949) 133–137.

J.I. Bluhm and R.J. Morrissey, inProceedings of the First International Conference on Fracture, Sendai, Japanese Society for Strength and Fracture of Materials, Vol. 3 (1966) 1739–1780.

J.E. Neimark,Journal of Applied Mechanics 35 (1968) 111–116.

F.A. McClintock, inPhysics of Strength and Plasticity, A.S. Argon (ed.), MIT Press, Cambridge (1969) 307–326.

J.R. Rice and M.A. Johnson, inInelastic Behavior of Solids, M.F. Kanninen et al. (eds.), McGraw-Hill (1970) 641–672.

C.A. Berg inInelastic Behavior of Solids, M.F. Kanninen et al. (eds.), McGraw-Hill (1970) 171–210.

G.R. Yoder,Metallurgical Transactions 3 (1972) 1851–1859.

C.D. Beachem and G.R. Yoder,Metallurgical Transactions 4 (1973) 1145–1153.

C.G. Chipperfield and J.F. Knott,Metals Technology 2 (1975) 45–51.

J.A. Van Den Avyle, “Correlation of Fractography, Microstructure, and Fracture Toughness Behavior of High Strength Alloys”, PhD thesis, Department of Metallurgy and Materials Science, Massachusetts Institute of Technology, Cambridge (1975).

J.W. Hancock and M.J. Cowling,Metal Science 14 (1980) 293–304.

H.C. Rogers,Transactions of the Metallurgical Society AIME 218 (1960) 498–506.

F.A. McClintock and S.J. Wineman,International Journal of Fracture 33 (1987) 285–295.

T. Kobayashi, G.R. Irwin, and X.J. Zhang, inFractography of Ceramic and Metal Failures, ASTM STP 827 (1984) 234–251.

D.A. Shockey and T. Kobayashi,Metallurgical Transactions 18A (1987) 1941–1949.

V. Tvergaard and A. Needleman,Acta Metallurgica 32 (1984) 157–169.

A. Needleman and V. Tvergaard,Journal of the Mechanics and Physics of Solids 35 (1987) 151–183.

N. Aravas and R.M. McMeeking,Journal of the Mechanics and Physics of Solids 33 (1985) 25–49.

N. Aravas and R.M. McMeeking,International Journal of Fracture 29 (1985) 21–38.

C.L. Hom and R.M. McMeeking, “Three-Dimensional Void Growth Before a Blunting Crack Tip”, submitted toJournal of the Mechanics and Physics of Solids (1988).

D.P. Clausing,Transactions of the American Society for Metals 60 (1967) 504–515.

F.J. Wu, “Loss of Fully-Plastic Crack Growth Ductility from Asymmetry in Plane Strain Bending”, M.S. thesis, Department of Mechanical Engineering, Massachusetts Institute of Technology, Cambridge (1987).

P. Ponte Castaneda,Journal of the Mechanics and Physics of Solids 35 (1987) 227–268.

P. Ponte Castafieda,Journal of Applied Mechanics 54 (1987) 379–387.

G.A. Kardomateas, “Mixed Mode I and II Fully Plastic Crack Growth from Simulated Weld Defects”, PhD. thesis, Department of Mechanical Engineering, Massachusetts Institute of Technology, Cambridge, (1985) Chapter 6.

G.A. Kardomateas and F.A. McClintock,International Journal of Fracture 40 (1989).

F.A. McClintock, inFracture, Vol. 3, H. Liebowitz (ed), Academic Press (1971) 136–141.

A.P. Green,Journal of the Mechanics and Physics of Solids 4 (1956) 259–268.

D.J.F. Ewing and R. Hill,Journal of the Mechanics and Physics of Solids 15 (1967) 115–124.

F.A. McClintock and M. Clerico,Journal of the Mechanics and Physics of Solids 28 (1980) 1–16.

R. Hill,The Mathematical Theory of Plasticity, Oxford University Press, Oxford (1985) 132–135.

F.A. McClintock, inFracture, Vol. 3, H. Liebowitz (ed.), Academic Press (1971) 67–68.

J.D. Landes and T.R. Leax, inFracture Mechanics: Fifteenth Symposium, ASTM STP 833, R.J. Sanford (ed.), (1984) 436–448.

J.D. Landes and D.E. McCabe, inElastic-Plastic Fracture: Second Symposium, Volume 2 – Fracture Resistance Curves and Engineering Applications, ASTM STP 803, C.F. Shih and J.F. Gudas (eds.), (1983) 723–733.

V.T. Troshchenko, V.V. Pokrovsky, and A.V. Prokopenko, inFracture, Vol. 3, D.M.R. Taplin (ed.), University of Waterloo Press, Waterloo (1977) 683–686.

J.A. Joyce and V. Culafic,International Journal of Fracture 36 (1988) 89–100.

W.G. Reuter, “Comparison Between Experimental and Analytical (Including Empirical) Results of Crack Growth Initiation Studies on Surface Cracks”, inThird International Symposium on Non-linear Fracture Mechanics (1986), ASTM STP 995 to appear (1989).

ASME Boiler and Pressure Vessel Code, Sec. III, Div. 1, Sub-section NB-2300 (1986) 15–18.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

McClintock, F.A. Reduced crack growth ductility due to asymmetric configurations. Int J Fract 42, 357–370 (1990). https://doi.org/10.1007/BF01185957

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01185957