Abstract

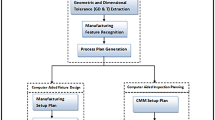

A program procedure for the design of fixtures to fit varying working conditions has been developed. The procedure is able to determine and evaluate optimal fixture configurations from the description of the workpiece and the assembly task. This process is done automatically. The application of this kind of procedure has the advantages of making the fixture design information completely modular and transparent, providing a better match to the working conditions, reducing leadtime, and generally providing a significant enhancement of fixture productivity and economy.

Similar content being viewed by others

References

A. Willy and T. Schmaus, “Entwicklungstendenzen und Stand der Technik flexibler Montagevorrichtungen”,Maschinenmarkt,96(34), pp. 42–46, 1990.

A. Willy and T. Schmaus, “Werkstückvorrichtungen für Aufgaben im Montagebereich flexibel gestaltet”,Maschinenmarkt,97(13), pp. 74–77, 1991.

B. S. Thompson, “Flexible fixturing — a current frontier in the evolution of flexible manufacturing cells”,ASME Paper, 84-WA/Prod-16, pp. 1–7, 1984.

A. Willy, “Flexible Vorrichtungen in der Montage”, inhandbuch Handhabungs-, Montage- und Industrierobotertechnik, vol. 3, Montagetechnik, 13. Nachlieferung, 4, pp. 7.3.1–7.3.23, 1990.

H. Mauri,Vorrichtungen I. Einleitung, Aufgaben und Elemente der Vorrichtungen, Springer Verlag, Berlin, Heidelberg, New York, 1976.

M. V. Gandhi and B. S. Thompson, “Phase change fixturing for flexible manufacturing systems”,Journal of Manufacturing Systems,4(1), pp. 29–39, 1985.

K. J. Siemens, “Flexible Halteeinrichtungen für Werkstücke”,VDI-Z,122(19), pp. 817–820, 1980.

A. Y. C. Nee, N. Bhattacharyya and A. N. Poo, “Applying AI in jigs and fixture design”,Robotics and Computer-Integrated Manufacturing,3(2), pp. 195–200, 1987.

D. T. Pham, M. J. Nategh and A. de Sam Lazaro, “A knowledge-based jig and fixture designers assistant”,The International Journal of Advanced Manufacturing Technology,4(1), pp. 26–45, 1989.

A. Markus, Z. Markusz, J. Farkas and J. Fileman, “Fixture design using Prolog: an expert system”,Robotics and Computer-Integrated Manufacturing,1(2), pp. 167–172, 1984.

B. S. Lim and J. A. G. Knight, “HOLDEX — holding device expert system”, inProceedings of the First International Conference on Application of Artificial Intelligence in Engineering Problems, Southampton, UK, pp. 483–501, April 1986.

G. Brüninghaus, “Rechnerunterstützte Konstruktion von Baukastenvorrichtungen”, RWTH Aachen, Fakultät Maschinenwesen, Diss. Dr-Ing, 1979.

K. Magnus and H. H. Müller,Grundlagen der Technischen Mechanik. 2. durchges, Teubner, Stuttgart, 1979.

N. N., Dubbel: Taschenbuch für den Maschinenbau. Korr. Nachdr. d. 15. korr. u. erg. Berlin, Springer, 1986.

M. Sayir and H. Ziegler,Mechanik 1. Grundlagen und Statik. Birkhäuser, Basel, 1982.

I. N. Bronstein and K. A. Semendjajew,Taschenbuch der Mathematik 21, Deutsch, Thun, Frankfurt/Main, 1981.

N. N.,Hütte: Die Grundlagen der Ingenieurwissenschaften 29, völlig neubearb. Berlin, Springer-Verlag, 1981.