Summary

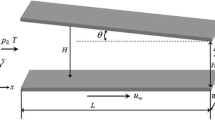

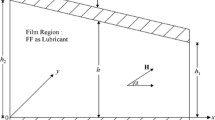

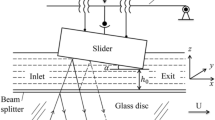

A theoretical analysis of finite slider bearings with the Bingham rheological model is presented which includes a full consideration for thermal effects. Full thermohydrodynamic (THD) as well as simplified ISOADI solutions are presented for a wide range of operating conditions. Results are authenticated with a number of published one-dimensional isoviscous solutions. An extensive set of parametric studies of the Bingham model together with an illustrative example is presented.

Similar content being viewed by others

Abbreviations

- a :

-

Clearance ratio

- B :

-

Pad length in the direction of motion (m)

- c o :

-

Lubricant specific heat (J/Kg K)

- f :

-

Friction coefficient

- F :

-

Frictional force (Pa)

- H b :

-

Thickness of the stationary component (m)

- h :

-

Film thickness (m)

- h 1,h 2 :

-

Maximum and minimum film thickness (m)

- h a,h b :

-

Height of the lower and upper boundary of core (m)

- h L,h H :

-

Height of the lower and upper boundary of fluid film (m)

- h conv :

-

Convective heat transfer coefficient (W/m2 K)

- K f :

-

Bearing characteristic number

- k o :

-

Thermal conductivity of the lubricant (W/m K)

- L :

-

Bearing length in the axial direction (m)

- m :

-

Slope of the slider bearing

- P :

-

Pressure (Pa)

- P a :

-

Ambient pressure (Pa)

- P L :

-

Average unit load (Pa)

- P max :

-

Maximum pressure (Pa)

- P s :

-

Supply pressure (Pa)

- Q in :

-

Inlet flow rate (m3/sec)

- Q leakage :

-

Leakage flow rate (m3/sec)

- S h :

-

Difference between the maximum and minimum film thickness (m)

- T :

-

Temperature (oC)

- T a :

-

Ambient temperature (oC)

- T b :

-

Stationary component temperature (oC)

- T max :

-

Maximum temperature (oC)

- T mean :

-

Mean temperature (oC)

- T s :

-

Lubricant temperature supplied (oC)

- T exit :

-

Exit temperature (oC)

- U 1,U 2 :

-

Velocity of the lower and upper surface along the film (m/sec)

- U L,U H :

-

Velocity of the lower and upper boundary of fluid film along the film (m/sec)

- U c,W c :

-

Velocity of core along the film and in the axial direction (m/sec)

- u, v, w :

-

Velocity component along, across the film and in the axial direction (m/sec)

- W :

-

Bearing load-carrying capacity (N)

- W L,W H :

-

Velocity of the lower and upper boundary of fluid film in the axial direction (m/sec)

- x, y, z :

-

Coordinate system (m)

- x b,y b :

-

Coordinate system used in the stationary component (m)

- β:

-

Temperature-viscosity coefficient (1/K)

- βτ :

-

Yield stress-temperature coefficient (1/K)

- \(\dot \gamma \) :

-

Shear rate (1/sec)

- ν:

-

Non-Newtonian viscosity (Pa·sec)

- ℵ1, ℵ2 :

-

Temperature-rise parameters

- Λ s :

-

Aspect ratio of the slider bearing

- μ:

-

Viscosity (Pa·sec)

- μ i :

-

Inlet viscosity (Pa·sec)

- μ eff :

-

Effective viscosity (Pa·sec)

- ρ o :

-

Density of the lubricant (Kg/m3)

- τ:

-

Shear stress (Pa)

- τ0 :

-

Critical shear stress (Pa)

References

Milne, A. A.: A Theory of rheodynamic lubrication. Kolloid Z.139, 96–101 (1954).

Osterle, F., Saibel, E.: The rheostat thrust bearings ASME-ASLE Conf. Paper 55-LUB. 6, Mechanical Engineering Abstract77, 1006 (1955).

Slibar, A., Paslay, P. R.: On the theory of grease-lubricated thrust bearings. ASME Trans.79, p. 1229 (1957).

Milne, A. A.: A theory of grease-lubrication of a slider bearing Proc. 2nd Intn. Cong. of Rheology, pp. 427–436 (1958).

Osterle, F., Charnes, A., Saibel, E.: The rheodynamic squeeze film Lubr. Eng.12, 33–36 (1956).

Batra, R. L.: Rheodynamic lubrication of a journal bearing. Appl. Sci. Res. Sec. A15, 331–344 (1965).

Wada, S., Hayashi, H., Haga, K.: Behavior of a bingham solid in hydrodynamic lubrication (Part 1, General theory). Bulletin of JSME16, 422–431 (1973).

Wada, S., Hayashi, H., Haga, K.: Behavior of a Bingham solid in hydrodynamic lubrication (Part 2, Application to step bearing). Bulletin of JSME16, 432–440 (1973).

Dareing D. W., Dayton, R. D.: Non-Newtonian behavior of powder lubricants mixed with ethylene glycol. STLE Tribology Transactions35, 114–120 (1992).

Dimarogonas, A., Kollias, A.: Electrorheological fluid-controlled “smart” journal bearings. STLE Tribology Transactions35, 611–618 (1992).

Heshmat, H.: The rheology and hydrodynamics of dry powder lubrication.. STLE Tribology Transactions34, 433–439 (1991).

Heshmat, H.: The quasi-hydrodynamic mechanism of powder lubrication: Part II-Lubricant film pressure profile. STLE Lubrication Engineering48, 373–383 (1992).

Tichy, J. A.: Hydrodynamic lubrication theory for the Bingham plastic model. J. Rheol.35, 477–496 (1991).

Dorier, C., Tichy, J. A.: Behavior of a Bingham-like viscous fluid in lubrication flows J. Non-Newtonian Fluid Mech.45, 291–310 (1992).

Dowson, D.: A generalized Reynolds equation for fluid film lubrication. Int. J. Mech. Sci.4, 159–170 (1962).

Paranjpe, R. S.: Analysis of non-Newtonian effects in dynamically loaded finite journal bearings including mass conserving cavitation. J. Tribology114, 736–744 (1992).

Khonsari, M. M., Jang, J. Y., Fillon, M.: On the generalization of thermohydrodynamic analyses for journal bearings. ASME J. Tribology118, 571–579 (1966).

Ezzat, H. A., Rhode, S. M.: A study of the thermodydrodynamic performance of finite slider bearings. J. Lubrication Technol.95, 298–307 (1973).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Jang, J.Y., Khonsari, M.M. On the thermohydrodynamic analysis of a Bingham fluid in slider bearings. Acta Mechanica 148, 165–185 (2001). https://doi.org/10.1007/BF01183676

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01183676