Abspract

The stress-strain behavior of carbon black filled rubber is recognized to be nonlinearly elastic in its main part (see e.g. Gent [1]). In addition, inelastic effects occur under monotonic and cyclic processes. The inelastic behavior includes nonlinear rate dependence as well as equilibrium hysteresis. Moreover, the first periods of a stress-strain curve differ significantly from the shape of subsequent cycles; a characteristic feature, which is called the Mullins effect, because it has been pointed out by Mullins [2]. All inelastic phenomena are strongly influenced by the volume fraction of the filler particles (see e.g. Payne [3], So and Chen [4], Meinecke and Taftaf [5]).

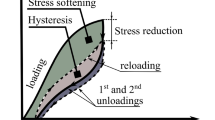

The aim of the present paper is to design a constitutive model, representing this kind of material behavior as a phenomenological theory of continuum mechanics. In order to motivate the basic structure of the constitutive theory, a series of uniaxial experiments between 100% in tension and 30% in compression are presented and analyzed. First of all, monotonic strain controlled experiments show the nonlinear rate dependence of the stress response. Then, a series of inserted relaxation periods at constant strain yields the monotonic equilibrium stress-strain curve, which is strongly nonlinear and unsymmetric with respect to the origin. Finally, cyclic experiments under strain control display pronounced hysteresis behavior. The hysteresis effects are mainly rate dependent, but there exists also a weak equilibrium hysteresis (compare to similar observations of Orschall and Peeken [6]). The Mullins effect corresponds to a softening phenomenon during the first few cycles. By means of an appropriate preprocess, this effect was excluded during the above experiments. Apart from the Mullins effect, neither hardening nor significant softening phenomena were observed in the context of cyclic loadings.

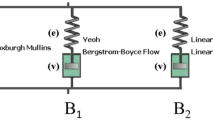

These results motivate the structure of a constitutive model of finite strain viscoplasticity: The total stress is decomposed into an equilibrium stress and an overstress, where the overstress is a rate dependent functional of the strain history. The overstress represents the rate dependence of the material behavior and tends asymptotically to zero during relaxation processes. The nonlinearity of the rate dependence is incorporated by means of a stress dependent relaxation time. The equilibrium stress is assumed to be a rate independent functional of the strain history. For this quantity, we make use of an arclength representation, which was originally introduced by Valanis [7]. In case of vanishing equilibrium hysteresis and vanishing rate dependence our constitutive model reduces to finite strain hyperelasticity, which is the first approximation of the constitutive properties. In more general cases the “main shape” of a stress-strain curve is determined by hyperelasticity, superimposed by rate dependent and equilibrium hysteresis. The representation of the Mullins effect is incorporated by a continuum damage model.

Some numerical simulations at the end of the paper demonstrate that the presented theory is able to represent the observed phenomena qualitatively and quantitatively with sufficient approximation.

Similar content being viewed by others

References

Gent AN (1962) Relaxation Processes in Vulcanized Rubber. I. Relation among Stress Relaxation, Creep, Recovery and Hysteresis. J. Appl. Polym. Sci. 6: 433–441

Mullins L (1969) Softening of Rubber by Deformation. Rubb. Chem. Technol. 42: 339–362

Payne AR (1962) The Dynamic Properties of Carbon Black Loaded Natural Rubber Vulcanizates. Part II. J. Appl. Polym. 6: 368–372

So H, Chen UD, (1991) A Nonlinear Mechanical Model for Solid-Filled Polymers. Polym. Eng. Sci. 6: 410–416

Meinecke EA, Taftaf MI (1988) Effect of Carbon Black on the Mechanical Properties of Elastomers. Rubb. Chem. Technol. 61: 534–547

Orschall, B, Peeken, H (1988) Viskoelastische Spannungs- und Dehnungsanalyse dreidimensionaler Gummibauteile. Forsch Ingenieurwes 57, No. 4: 132–136

Valanis KC (1971) A Theory of Viscoplasticity without a Yield Surface. Arch. Mech. 23, 4: 517–533

Hamed GR, Hatfield, S (1989) On the Role of Bound Rubber in Carbon Black Reinforcement. Rubb. Chem. Technol. 62: 143–156

Bueche, F (1961) Mullins Effect and Rubber-Filler Interaction. J. Appl. Polym. Sci. 5, 15: 271–281

James AG, Green A, Simpson GM (1975) Strain Energy Functions of Rubber. I. Characterisation of Gum Vulcanizates. J. Appl. Polym. Sci. 19: 2033–2058

James AG, Green A (1975) Strain Energy Functions of Rubber. II. The Characterization of Filled Vulcanisates. J. Appl. Polym. Sci. 19: 2033–2058

Liu MC, Krempl E (1979) A Uniaxial Viscoplastic Model Based on Total Strain and Overstress. J. Mech. Phys. Solids 27: 377–391

Christensen RM (1980) A Nonlinear Theory of Viscoelasticity for Application to Elastomers. J. Appl. Mech. 47: 762–768

Browning R, Gurtin ME, Williams WO (1984) A One-Dimensional Viscoplastic Constitutive Theory for Filled Polymers. Int. J. Solids Struct. 921–934

Lubliner J (1985) A Model of Rubber Viscoelasticity. Mech. Res. Comm. 12(2): 93–99

Kachanov LM (1986) Introduction to Continuum Damage Mechanics. Martinus Nijhoff Publishers, P.O. Box 163, 3300 AD Dordrecht, Netherlands

Simo JC (1987) On a fully three-dimensional Finite-Strain Viscoelastic Damage Model. Formulation and Computational Aspects. Comput Meth Appl Mech Eng 60: 153–173

Harwood JAC, Mullins L, Payne AR (1965) Stress Softening in Natural Rubber Vulcanizates. Part II. Stress Softening Effects in Pure Gum and Filler Loaded Rubbers. J. Appl. Polym. Sci. 9: 3011–3021

Lemaitre J, Chaboche JL (1988) Mechanique des Materiaux Solides. Bordas Paris

Haupt P, Tsakmakis C (1989) On the Application of Dual Variables in Continuum Mechanics. Cont. Mech. Thermodyn. 1: 165–196

Haupt P (1971) Viskoelastizitdt Inkompressibler Isotroper Stoffe.: Approximation der Allgemeinen Materialgleichung. Dissertation, TU Berlin

Govindjee S, Simo J (1991) A Micro-Mechanically Based Continuum Damage Model for Carbon Black Filled Rubbers Incorporating Mullins' Effect. J. Mech. Phys. Solids 39, 1: 87–112

Mullins L, Tobin NR (1957) Theoretical Model for the Elastic Behavior of Filler Reinforced Vulcanized Rubber. Rubb. Chem. Technol. 30: 551–571

Harwood JAC, Payne AR (1966) Stress Softening in Natural Rubber Vulcanizates. Part III. Stress Carbon Black Filled Vulcanizates. J. Appl. Polym. Sci. 10: 315–324

Bruhns OT, Lehmann T, Pape A (1992) On the Description of Transient Cyclic Hardening Behavior of Mild Steel CK 15. Int. J. Plasticity 8: 331–359

Johnson MA, Beatty MF (1993) The Mullins Effect in uniaxial Extension and its Influence on the transverse vibration of a Rubber String. Cont. Mech. Thermodyn. 5: 83–115

Johnson MA, Beatty MF (1993) A Constitutive Equation for the Mullins Effect in Stress Controlled Uniaxial Extension Experiments. Cont. Mech. Thermodyn. 5: 301–318

van den Bogert, PAJ, de Borst R (1994) On the Behavior of Rubberlike Materials in Compression and Shear. Arch. Appl. Mech. Vol. 64: 136–146

Haupt P, Lion A (1995) Experimental Identification and Mathematical Modeling of Viscoplastic Material Behavior. Cont. Mech. Thermodyn. 7: 73–96

Hausler K, Sayir MB (1995) Nonlinear Viscoelastic Response of Carbon Black Reinforced Rubber Derived from Moderately Large Deformations in Torsion. J. Mech. Solids 43: 295–318

Beatty MF, Stalnaker DO (1986) The Poisson Function of Finite Elasticity. J. Appl. Mech. 53: 807–813

Mullins L (1947) Effect of Stretching on the properties of Rubber. J. Rubb. Res. 16: 275–289

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lion, A. A constitutive model for carbon black filled rubber: Experimental investigations and mathematical representation. Continuum Mech. Thermodyn 8, 153–169 (1996). https://doi.org/10.1007/BF01181853

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01181853