Abstract

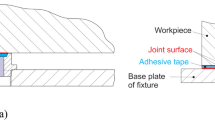

A novel quick action flexible fixture for two-dimensional clamping is fitted with sensors for automatically measuring the positions of the clamping surfaces and the vice opening. An algorithm is proposed to determine the location and orientation of the workpiece on the fixture. The NC codes preprogrammed with a given origin and orientation can then be modified with these data to appropriately transposed coordinates, which can then be downloaded to the NC controller for NC machining. With this system, the time and cost of fixturing will be greatly reduced.

Similar content being viewed by others

References

A. S. Miller and R. G. Hannam, “Computer aided design using a knowledge base approach and its application to the design of jigs and fixtures”,Proceedings of the Institute of Mechanical Engineers,199(B1), pp. 227–234, 1985.

W. Jiang, Z. Wang and Y. Cai, “Computer aided group fixture design”,Annals of CIRP,137(1), pp. 145–148, 1988.

A. R. Darvishi and K. F. Gill, “Knowledge representation database for the development of a fixture design expert system”,Proceedings of the Institute of Mechanical Engineers,202(B1), pp. 37–49, 1988.

J. R. Boerma and H. J. Kals, “FIXES, a system for automatic selection of set-up and design of fixtures”,Annals of the CIRP,37(1), pp. 443–446, 1988.

J. R. Boerma and H. J. Kals, “Fixing design with FIXES: the automatic selection of position, clamping and support feature for prismatic parts”,Annals of CIRP,138(1), pp. 399–402, 1989.

D. Pham, M. Nategh and A. de Sam Lazaro, “A knowledge-based jig-and-fixture designers' assistant”,The International Journal of Advanced Manufacturing Technology,4, pp. 26–45, April 1989.

H. Sakurai, “Automatic setup planning and fixture design for machining”,Journal of Manufacturing Systems,11(1), pp. 30–37, 1992.

E. C. DeMeter, “Restraint analysis of fixtures which rely on surface contact”,Transactions ASME, Journal of Engineering for Industry,116, pp. 207–215, May 1994.

C. L. Liu, “A systematic conceptual design of modular fixtures”,Advanced Manufacturing Technology,9, pp. 217–224, 1994.

A. Drake, “Fixture design: working with modules”,Manufacturing Engineering, pp. 35–38, January 1984.

H. Takao, “Adaptability of a modular fixturing system to factory automation”,Bulletin of the Japan Society of Precision Engineering,22(1), pp. 1–5, March 1988.

P. Grippo, M. Gandhi and B. Thompson, “The computer-aided design of modular fixturing system”,International Journal of Advanced Manufacturing Technology,2(2), pp. 75–88, 1987.

M. Gandhi and B. Thompson, “Automated design of modular fixtures for flexible manufacturing system”,Journal of Manufacturing Systems,15(4), pp. 243–252, 1986.

C. L. Liu, “A functional check approach to rationalise design and manufacturing problem”,The Fifth International Conference on Manufacturing Enginering 1990, Wollongong, 11–13 July 1990, pp.297–300, 1990.

C. L. Liu, “The main constructing stages of modular fixtures”,SME Technical Paper MS90-302, 1990.

J. H. Buitrago and K. Youcef-Toumi, “Design of active modular and adaptable fixtures operated by robot manipulators”,ASME Proceedings USA-Japan Symposium on Flexible Automation, July 1988, pp. 467–474, 1988.

M. R. Cutkosky, E. Kurokawa and P. K. Wright, “Programmable conformable clamp”,Proceedings AUTOFACT 4, pp. 1151–1158, November 1982.

“Cerro alloy physical data and applications”, Publication HQ-793-P, Cerro Metal Products Corporation, Bellfonre, PA, 1984.

J. E. Stangrom, “Electroheological fluid,”Physical Technology,14, pp. 290–296, 1983.

D. A. Brooks, “Electroheological devices”,Chartered Mechanical Engineer,29(9), pp. 92–95, 1982.

M. V. Gandhi and B. S. Thompson, “Phase change fixturing for flexible manufacturing system”,Journal of Manufacturing Systems,4(1), pp. 29–39, 1985.

M. V. Gandhi, B. S. Thompson and D. J. Mass, “Adaptable fixture design: an analytical and experimental study of fluidizedbed fixturing”,ASME Journal of Mechanisms, Transmissions, and Automation in Design,108, pp. 15–21, 1986.

J. E. Griffith, D. D. Grossman, P. M. Will and R. I. Garrison, “Quasi-liquid vise for a computer controlled manipulator”,IBM Technical Report RCA 5451 (no. 23797), Yorktown Heights, NY, 1975.

A. H. Slocum, J. Perisand and A. Donmez, “Development of a flexible automated fixturing system”,SME Technical Paper MR86-126, 1986.

K. Tuffentsammer, “Automatic loading of machining systems and automatic clamping of workpieces”,Annals of CIRP,30(2), pp. 553–558, 1981.

N. Langes, M. V. Gandhi, B. S. Thompson and D. J. Desai, “An experimental evaluation of the capabilities of a fluidized bed fixturing system”,International Journal of Advanced Manufacturing Technology,4, pp. 192–206, 1989.

K. Kurz, K. Crang, B. Wolf and F. Stolfi, “Developing a flexible automated fixturing device”,Mechanical Enginering, pp. 59–63, July 1994.

C. L. Liu,Proceedings of the Twelfth International Conference on Production Research, Finland, pp. 237–238, August 1993.

T. H. Yang, US Patent 4632374, 4632375, 1986.

T. H. Yang, EPC Patent 0104286, 1986.

T. H. Yang, Japan Patent 1826467, 1991.

F. Reuleaux,Kinematics of Machinery, Dover, New York, 1975.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lu, SS., Chu, JL. & Jang, HC. Development of a novel coordinate transposing fixture system. Int J Adv Manuf Technol 13, 350–358 (1997). https://doi.org/10.1007/BF01178255

Issue Date:

DOI: https://doi.org/10.1007/BF01178255