Summary

Theoretical and experimental analyses have been carried out for determining the injection condition below which the formation of air core does not take place in the course of flow of a time-independent power-law fluid through a swirl nozzle. Analytical solution lends one distinct value of generalized Reynolds number at the inlet to a nozzle below which the air core is not formed. Experiments reveal that there exist two limiting values of such generalized Reynolds number regarding the formation of air core in a nozzle. One value being the upper limit below which steady flow occurs without air core, the other one is the lower limit above which steady flow with fully developed air core persists. In between these two limiting values, there prevails a transition zone through which fully developed air core is set up within the nozzle. For all the nozzles, theoretical results are in fair agreement with the experimental values of upper limit of generalized Reynolds numbers with respect to steady flow without air core. Amongst all the pertinent independent geometrical parameters of a nozzle, the orifice-to-swirl chamber-diameter ratio has the remarkable influence on generalized Reynolds number describing the initiation of air core.

Similar content being viewed by others

Abbreviations

- D 1 :

-

Swirl chamber diameter

- D 2 :

-

Orifice diameter

- D s :

-

Diameter of tangential entry ports

- E :

-

A non-dimensional parameter defined by Eq. (9)

- E R :

-

A non-dimensional parameter defined by Eq. (25)

- K :

-

Flow consistency index

- L 1 :

-

Length of the swirl chamber

- n :

-

Flow behaviour index

- P :

-

Static pressure inside the nozzle

- P b :

-

Back-pressure of the nozzle

- Q :

-

Volume flow rate

- R :

-

Radius vector or longitudinal coordinate with respect to spherical coordinate system (Fig. 3)

- R 1 :

-

Radius of the swirl chamber

- R 2 :

-

Radius of the orifice

- \(Re_{G_i }\) :

-

Generalized Reynolds number at the inlet to the nozzle

- \(\bar Re_{G_i }\) :

-

Limiting value of generalized Reynolds number describing initiation of air core

- R z :

-

Radius at any section

- r :

-

Radial distance from the nozzle axis

- r a :

-

Air core radius

- u :

-

Longitudinal component of velocity with respect to spherical coordinate system (Fig. 3)

- V r :

-

Radial velocity component

- V z :

-

Axial velocity component

- V ϕ :

-

Tangential velocity component

- \(V_{\phi _i }\) :

-

Tangential velocity at inlet to the nozzle

- v :

-

Component of velocity in the axial plane perpendicular toR (Fig. 3)

- w :

-

Component of velocity perpendicular to axial plane with respect to the spherical coordinate system (Fig. 3)

- z :

-

Distance along the nozzle axis from its inlet plane

- α:

-

Half of the spin chamber angle

- δ:

-

Boundary layer thickness measured perpendicularly from the nozzle wall

- δ2 :

-

Boundary layer thickness at the orifice

- θ:

-

Angle, which a radius vector makes with the nozzle axis, in spherical coordinate system (Fig. 3)

- ϱ:

-

Density of the fluid

- ϕ:

-

Running coordinate in the azimuthal direction with respect to the cylindrical polar coordinate system as shown in Fig. 3

- Ω:

-

Circulation constant

References

Som, S. K., Mukherjee, S. G.: Theoretical and experimental investigations on the formation of air core in a swirl spray atomizing nozzle. Appl. Sci. Res.36, 173 (1980).

Som, S. K.: Theoretical and experimental studies on the formation of an air core in swirl spray pressure nozzle using a power law non-Newtonian fluid. Appl. Sci. Res.40, 71 (1983).

Som, S. K., Mukherjee, S. G.: Theoretical and experimental investigations on the coefficient of discharge and spray cone angle of a swirl spray atomizing nozzle. Acta Mechanica36, 79 (1980).

Taylor, G. I.: The boundary layer in the converging nozzle of swirl atomizer. Quart. J. Mech. and Appl. Math.3, 129 (1950).

Som, S. K.: Theoretical and experimental studies on the coefficient of discharge and spray cone angle of a swirl spray pressure nozzle using a power-law non-Newtonian fluid. J. Non-Newtonian Fluid Mech.12, 39 (1983).

Tate, R. W., Marshall, W. R.: Atomization by centrifugal nozzles. J. Chem. Engg. Prog.49, 169 (1953).

Taylor, G. I.: The mechanics of swirl atomizers. Proc. 7th Int. Cong. for Applied Mechanics, Vol. 2, part 1, p. 280 (1948).

Binnie, A. M., Harris, D. P.: The application of boundary layer theory to swirling flow through a nozzle. Quart. J. Mech. and Appl. Math.3, 89 (1950).

Cooke, J. C.: On Pohlhausen's method with application to a swirl problem of Taylor. J. aero. Sci.19, 486 (1952).

Binnie, A. M.: Viscosity effects in the nozzle of a swirl atomizer. Quart. J. Mech. Appl. Math.8, 394 (1955).

Binnie, A. M., Teare, J. D.: Experiments on the flow of a swirling water through a pressure nozzle and on open trumpet. Proc. Roy. Soc. (London)235 A, 78 (1956).

Binnie, A. M., Hakings, G. A., Kamel, M. Y. M.: The flow of swirling water through a convergent divergent nozzle. J. Fluid Mech.3, 261 (1957).

Author information

Authors and Affiliations

Additional information

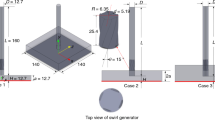

With 8 Figures

Rights and permissions

About this article

Cite this article

Som, S.K., Biswas, G. Initiation of air core in a swirl nozzle using time-independent power-law fluids. Acta Mechanica 51, 179–197 (1984). https://doi.org/10.1007/BF01177071

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF01177071