Summary

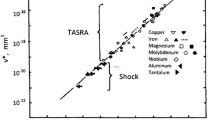

Processes on the microscale determine the macroscopic behaviour of metallic materials and should therefore be considered during the development of constitutive macroscopic equations used for engineering calculations. The article reviews the mathematical formulation of the most significant of these processes, such as dislocation motion due to thermal and mechanical activation and the development of internal structures during plastic deformation. It describes the consideration of these relations in a stochastic model for the inelastic behaviour of metals and shows the comparison between predictions of this model and experimental findings.

Similar content being viewed by others

References

Conrad, H.: Thermally activated deformation of metals. J. Metals, 582–588 (1964).

Nadgornyi, E.: Dislocation dynamics and mechanical properties of crystals. Prog. Mat. Sci.31, 1–535 (1988).

Kocks, U. F., Argon, A. S., Ashby, M. F.: Thermodynamics and kinetics of slip. Prog. Mat. Sci.19, 1–17 (1975).

Orowan, E.: Problems of plastic gliding. Proc. Phys. Society52, 8–22 (1940).

Nohara, A.: Dislocation-structure changes during the dip-tests and the dynamical internal stress in Al−Mg alloys at high temperatures. Phys. Stat. Sol. A88A, 213–222 (1985).

Barrett, C. R., Nix, W. D.: A model for steady state creep based on the motion of jogged screw dislocations. Acta Metall.13, 1247–1258 (1965).

Bengus, V. Z.: Effects of the dislocation collective behaviour in plasticity of single crystals. Cryst. Res. Technol.8, 757–761 (1984).

Frost, H. J., Ashby, M. F.: Motion of a dislocation acted on by a viscous drag through an array of discrete obstacles. Int. J. Non-Linear Mech.42, 5273–5279 (1971).

Balasubramanian, N., Li, J. C. M.: The activation areas for creep deformation. J. Mat. Sci.5, 434–444 (1970).

Kocks, U. F., Dawson, P. R., Follansbee, P. S.: Physical and phenomenological plasticity. Los Alamos, Center for Materials Science, LA-UR-86-2672 (1986).

Frost, H. J., Ashby, M. F.: Deformation-mechanism maps. New York: Pergamon Press 1982.

Raj, S. V., Langdon, T. G.: Creep behavior of copper at intermediate temperatures I. Mechanical characteristics. Acta Metall.37, 843–852 (1989).

Krashchenko, V. P., Statsenko, V. E.: Effect of temperature and strain rate on basic processes controlling the strength of copper. Strength Mat.13, 487–492 (1981).

Nabarro, F. R. N.: Steady-state diffusional creep. Phil. Mag.16, 231–237 (1967).

Weertman, J.: Dislocation climb theory of steady-state creep. Trans, ASM., 681–694 (1968).

Pueschl, W., Schoeck, G.: Calculation of cross-slip parameters in f.c.c. crystals. Mat. Sci. Eng.A 164, 286–289 (1993).

Conrad, H.: An investigation of the rate controlling mechanism for plastic flow of copper crystals at 90 K and 170 K. Acta Metall.6, 339–350 (1958).

Gindin, J. A., Nechrolod, N. K., Starodubor, Y. D.: Effect of staged low-temperature creep on the resistivity and mechanical properties of copper. Phys. Met. Metall.26, 107–114 (1968).

Guyot, P., Dorn, J. E.: A critical review of the Peierls mechanism. Can. J. Phys.45, 983–1017 (1967).

Herring, C.: Diffusional viscosity of a polycrystalline solid. Int. J. Non-Linear Mech.21, 437–445 (1950).

Coble, R. L.: A model for boundary diffusion controlled creep in polycristalline materials. J. Appl. Phys.34, 1679–1682 (1963).

Sherby, O. D., Miller, A. K.: Combining phenomenology and physics in describing the high temperature mechanical behavior of crystalline solids. J. Eng. Mat. Tech.101, 387–395 (1979).

Conrad, H.: The role of grain boundaries in creep and stress rupture. In: Mechanical behavior of materials (Dorn, J. E., ed.), pp. 218–269, 60–16667. New York: McGraw Hill 1961.

Exell, S. F., Warrington, D. H.: Subgrain boundary migration in aluminium. Phil. Mag.26, 1121 (1972).

Biberger, M., Blum, W.: Subgrain boundary migration during creep of LiF (I. Recombination of subgrain boundaries). Phil. Mag.A.66, 757–770 (1992).

Biberger, M., Blum, W.: Subgrain boundary migration during creep of LiF (II. Constant-Stress Experiments). Phil. Mag.A.66, 27–40 (1992).

Seeger, A., Schoeck, G.: Die Aufspaltung von Versetzungen in Metallen dichtester Kugelpackung. Acta Metall.1, 519–536 (1953).

Duesbery, M. S., Lonat, N. P., Sadananda, K.: The mechanics and energetics of cross-slip. Acta Metall.40, 149–158 (1992).

Weertman, J.: Steady-state creep through dislocation climb. Int. J. Non-Linear Mech.28, 362 (1957).

De Hosson, J. T., Boom, G., Schlagowski, U.: Solution hardening in Al−Zn alloys. Acta Metall.34, 1571–1583 (1986).

Mukherjee, A. K., Mote, J. D., Dorn, J. E.: Strain hardening of single aluminium crystals during polyslip. Trans. Met. Soc. AIME233, 1559–1565 (1965).

El-Magd, E., Shaker, C.: Determination of internal back stress under time-dependent creep-conditions. 4th Int Conf. on Creep and Fracture of Engineering Materials and Structures 1990.

Ziaai-Moayyed, A. A.: Back stresses in monotonic and cyclic deformation: transient and steady-state-behavior. Dissertation, Stanford University 1981.

Butt, M., Feltham, P.: Review — solid-solution hardening. J. Mat. Sci.28, 2557–2576 (1993).

Holt, D. L.: Dislocation cell formation in metals. Int. J. Non-Linear Mech.41, 3197–3201 (1970).

McQueen, H. J., Hockett, J. E.: Microstructures of aluminium compressed at various rates and temperatures. Metall Trans.1, 2997–3004 (1970).

Haasen, P.: Plastic deformation of nickel single crystals at low temperatures. Phil. Mag.3, 348–418 (1958).

Hirsch, P. B., Mitchell, T. E.: Dislocation structures in deformed single crystal and work-hardening theories. In: Work hardening (Hirth, J. P., Wertman, J., eds.). New York: Gordon and Breach 1968.

Friedel, J.: On the linear work hardening rate of f.c.c. single crystals. Phil. Mag.46, 1169–1186 (1955).

Friedel, J., Saada, G.: Introductory remarks on the nature of strain hardening in single crystals. In: Work hardening (Hirth, J. P., Weertman, J., eds.). New York: Gordon and Breach 1968.

Kuhlmann-Wilsdorf, D.: Unified theory of stages II and III of work-hardening in pure f.c.c. metal crystals. In: Work hardening (Hirth, J. P., Weertman, J., eds.). New York: Gordon and Breach 1968.

Hirsch, P. B.: Work hardening. In: The physics of metals S. Defects (Hirsch, P. B.,ed.), pp. 189–246. Cambridge: University Press 1975.

Seeger, A.: Recent progress in the understanding of work-hardening of f.c.c. single crystals. In: Work hardening (Hirth, J. P., Weertman, J., eds.). New York: Gorden and Breach 1968.

Basinski, Z.'S.: Thermally activated glide in face-centred cubic metals and its application to the theory of strain hardening. Phil. Mag.4, 393–432 (1959).

Mughrabi, H.: Description of the dislocation structures after unidirectional deformation at low temperature. In: Constitutive equations in plasticity (Argon, A. S., ed.), pp. 199–250. MIT-Press: Cambridge 1975.

Mitra, S. K., Osborne, P. W., Dorn, J. E.: On the intersection mechanism of plastic deformation in aluminium single crystals. Trans. Metall. Soc. AIME221, 1206–1214 (1961).

Hasegawa, T., Yakou, T., Karashima, S.: Deformation behaviour and dislocation structures upon stress reversal in polycrystalline aluminium. Mat. Sci. Eng.20, 267–276 (1975).

Mecking, H.: Strain hardening and dynamic recovery. In: Dislocation modelling of physical systems (Ashby, M. F., ed.), pp. 197–202. Proc. on the Int. Conf., Gainesville. Oxford: Pergamon Press 1981.

Mecking, H., Gottstein, G.: Recovery and recrystallization during deformation. In: Recrystallization of metallic materials (Haessner, F., ed.). Stuttgart: Dr. Rieder Verlag 1978.

Kuhlmann-Wilsdorf, D.: Theory of plastic deformation: properties of low energy dislocation structures. Mat. Sci. Eng.A 113, 1–39 (1989).

Seeger, A.: The mechanism of glide and work-hardening in f.c.c. and h.c.p. metals. In: Dislocation and mechanical properties of crystals (Fisher, J. C., Johnston, W. G., Thomson, R., eds.), pp. 243–329 General Electric 1957.

Mecking, H., Kocks, U. F.: Kinetics of flow and strain-hardening. Acta Metall.10, 1865–1875 (1981).

Follansbee, P. S., Kocks, U. F.: A constitutive description of the deformation of copper based on the use of the mechanical treshold as an internal state variable. Acta Metall.36, 81–93 (1988).

Mecking, H., Luecke, K.: Analysis of stage III hardening of f.c.c. metals on the basis of themally activated cross slip. Second Intern. Conf. on the Strength of Metals and Alloys, pp. 470–474 (1970).

Aernoudt, E., Gil-Sevillano, J., Van Houtte, P.: Structural background of yield and flow. In: Constitutive relations and their physical basis (Andersen, S. I, ed.), pp. 1–38. Denmark, Riso Natl. Lab. 1987.

Gil Sevillano, J.: The cold worked — state. In: Rekristallisation '92, pp. 19–27 (1992).

Mecking, H., Estrin, Y.: Microstructure-related constitutive modelling of plastic deformation. In: Constitutive relations and their physical basis (Andersen, S. I, ed.), pp. 123–145 Denmark: Riso Natl. Lab. 1987.

Nix, W. D., Gibeling, J. C., Huges, D. A.: Time-dependent deformation of metals. Metall. Trans.A 16, 2215–2226 (1985).

Nix, W. D., Ilschner, B.: Mechanisms controlling creep of single phase metals and alloys. In: Strength of metals and alloys, ICSMA 5 (Haasen, P., Gerold, V., Kostorz, G., eds). Aachen: Pergamon Press 1979.

Mughrabi, H.: Dislocation wall and cell structures and long-range internal stresses in deformed metal crystals. Acta Metall.31, 1367–1379 (1983).

Blum, W., Straub, S., Vogler, S.: Creep of pure materials and alloys. In: High temperatures materials and processes (Blum, W., Straub, S., Vogler, S., eds.), pp. 31–47. Erlangen: Inst. f. Werkstoffe 1993.

Schlums, H.: Ein stochastisches Werkstoffmodell zur Beschreibung von Kriechen und zyklischem Verhalten metallischer Werkstoffe. Braunschweig Series on Mechanics,5, Brauschweig: Mechanik-Zentrum 1992.

Miller, A. K.: An inelastic constitutive model for monotonic, cyclic and creep deformation: Part I: Equations development and analytical procedures. J. Eng. Mat. Tech.97, 106–113 (1976).

Chan, K. S., Lindholm, U. S., Bodner, S. R.: High temperature inelastic deformation under uniaxial loading: theory and experiment. J. Eng. Mat. Tech.111, (1989).

Hasegawa, T., Ikeuchi, Y., Karashima, S.: Internal stress and dislocation structure during sigmoidal transient creep. Met. Sci. J.6, 78–82 (1972).

Heinrich, H., Neuhaus, R., Schwink, C.: Dislocation structure and densities in tensile deformed CuMn crystals oriented for single glide. Phys. Stat. Sol.A 131, 299–305 (1992).

Amodeo, R. J.: Dynamic simulation of dislocation pattern formation in metals during high temperature monotonic and cyclic deformation Dissertation, University of California 1988.

Amodeo, R. J., Ghoniem, M. M.: Dislocation dynamics I. A proposed methology for deformation micromechanics. Phys. Rev.B 41, 6958–6976 (1990).

Hesselbarth, H.: Simulation von Versetzungsstrukturbildung, Rekristallisation und Kriechschädigung mit dem Prinzip der Zellulären Automaten. Braunschweig Series on Mechanics4, Braunschweig: Mechanik-Zentrum 1992.

Nordstrom, T. V., Barrett, C. R.: Recovery of high temperature deformed Ni−Al alloys. J. Mat. Sci. 1052–1060 (1972).

Ahlquist, C. N., Gasca-Neri, R., Nix, W. D.: A phenomenological theory of steady state creep based on average internal and effective stresses. Acta Metall.18, 663–671 (1970).

Kocks, U. F., Mecking, H.: A mechanism for static and dynamic recovery. In: Strength of metals and alloys (Haasen, P., Gerold, V., Kostorz, G., eds.), pp. 345–350. Proc. of the 5th HICSMA-Conf., Aachen: Pergamon Press 1980.

Kassner, M. E., Miller, A. K., Sherby, O. D.: The separate roles of subgrains and forest dislocations in the isotropic hardening of type 304 stainless steel. Metall. Trans.A 13, 1977–1986 (1982).

Argon, A. S., Takeuchi, C.: Internal stresses in power-law creep. Acta Metall.29, 1877–1884 (1981).

Gottstein, G., Argon, A. S.: Dislocation theory of strain hardening and steady state deformation in creep and constant strain rate tests. In: Creep and fracture of engineering materials and structures (Wilshire, B., Owen, D. R. J., eds.), pp. 15–26. Swansea: Pineridge Press 1984.

Gottstein, G., Argon, A. S.: Dislocation theory of steady state deformation and its approach in creep and dynamic tests. Acta Metall.35, 1261–1271 (1987).

Prinz, F. B., Argon, A. S.: The evolution of plastic resistance in large strain plastic flow of single phase subgrain forming metals. Acta Metall.32, 1021–1030 (1984).

Mecking, H.: Description of hardening curves of f.c.c. single and polycrystals. In: Work hardening in tension and fatigue (Thompson, A. W. ed.), pp. 67–88. Ohio 1975.

Prinz, F., Argon, A. S., Moffatt, W. C.: Recovery of dislocation structures in plastically deformed copper and nickel single crystals. Acta Metall.30, 821–830 (1982).

Kocks, U. F.: Law for work hardening and low-temperature creep. J. Eng. Mat. Tech. Trans of the ASME97, 76–85 (1976).

Cernocky, E. P., Krempl, E.: A non-linear uniaxial integral constitutive equation incorporating rate effects, creep and relaxation. Int. J. Non-Linear Mech.14, 183–203 (1979).

Chaboche, J. L.: Constitutive equations for cyclic plasticity. Int. J. Plast.5, 247–302 (1989).

Haupt, P., Korzen, M.: A new constitutive model of the phenomenological representation of rate-dependent and rate-independent material behavior. Proc. of Mecamat, The Inelastic Behavior of Solids, pp. 41–52 (1989).

Szepan, F.: Ein elastisch-viskoplastisches Stoffgesetz zur Beschreibung großer Formänderungen unter Berücksichtigung der thermomechanischen Kopplung. Mitteilungen aus dem Institut für Mechanik70. Bochum 1989.

Estrin, Y.: A unified constitutive model with one structure parameter. Proc. of Mecamat, Inelastic Behavior of Solids, pp. 537–546 (1989).

Feltham, P.: A stochastic model of creep. Phys. Stat. Sol.30, 135–146 (1968).

Täubert, P.: Eine Kriechtheorie für Metalle unter Berücksichtigung von Verfestigung und Erholung. Deutsche Akademie der Wissenschaften, Klasse Mathematik, Physik, Technik.7, (1958).

Steck, E. A.: A stochastic model for the high-temperature plasticity of metals. Int. J. Plast.5, 243–258 (1985).

Steck, E. A.: A stochastic model for the interaction of plasticity and creep in metals. Nucl. Eng. Design.114, 285–294 (1989).

Gerdes, R.: Ein stochastisches Werkstoffmodell für das inelastische Materialverhalten metallischer Werkstoffe im Hoch- und Tieftemperaturbereich. Braunschweiger Series on Mechanics20, Braunschweig: Mechanik-Zentrum 1995.

Gifkins, R. C.: Transitions in creep behavior. J. Mat. Sci.5, 156–165 (1970).

Siethoff, H.: Change in steady — state deformation mechanism of f.c.c. metals at intermediate temperatures. Z. Metallkunde77 (1986).

Mecking, H.: Bestimmung der Werkstoffparameter für das Kriechen von Aluminium-Legierungen. Abschlußbericht zum DFG-Forschungsvorhaben Me 428/7 (1989).

Steck, E. A., Gerdes, R., Lewerenz, M.: A stochastic constitutive model for high temperatures and its application to three-dimensional structures. In: Mathematical Modelling and Scientific Computing, special issue on Materials Modelling (to appear).

Rie, K. T., Wittke, H.: Inelastisches Stoffgesetz und zyklisches Werkstoffverhalten im LCF-Bereich. In: Stoffgesetz für das inelastische Verhalten metallischer Werkstoffe. SFB 319. Braunschweig 1993.

Author information

Authors and Affiliations

Additional information

Dedicated to Professor Dr.-Ing. E. h. Dr. h. c. mult. E. Stein on the occasion of his 65th birthday

Rights and permissions

About this article

Cite this article

Steck, E.A., Gerdes, R. Consideration of processes on the microscale of metallic materials for the development of constitutive models. Acta Mechanica 120, 1–30 (1997). https://doi.org/10.1007/BF01174313

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01174313