Conclusions

-

1.

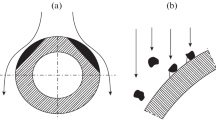

Failure of heat exchangers made of steels Kh23N18 and Kh24N12SL results from carburizing and sulfur-alkali corrosion in the presence of compounds of vanadium forming a low-melting eutectic preferentially in austenite grain boundaries.

-

2.

The corrosion rate of heat exchangers in mazout furnaces is three times the corrosion rate of heat exchangers in gas furnaces.

-

3.

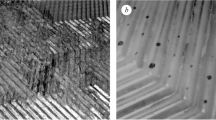

In heat exchangers that increase the gas flow rate the surface is attacked due to erosion-abrasion of the protective oxide film. Free oxidation and carburizing of the steel occur in this case.

Similar content being viewed by others

Additional information

State All-Union Scientific-Research Institute of the Cement Industry. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 56–58, March, 1977.

Rights and permissions

About this article

Cite this article

Tylkin, M.A., Bogomolov, B.N. & Sharkova, A.M. Mechanism of failure of heat exchangers in cement furnaces. Met Sci Heat Treat 19, 222–224 (1977). https://doi.org/10.1007/BF01167006

Issue Date:

DOI: https://doi.org/10.1007/BF01167006