Abstract

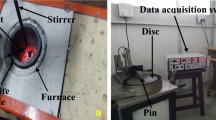

The effect of fibre orientation on the dry sliding wear of continuous B(SiC) fibre reinforced aluminium alloy composites was investigated using a pin-on-disc wear testing machine. The metal-matrix composites (MMC) samples were tested in the normal (N), parallel (P) and antiparallel (AP) orientations sliding against a steel counter disc at a fixed speed of 1 m s−1 under loads of from 12 to 60 N.

The results showed that for the matrix alloy and MMCs, the average wear increased linearly with load. Wear of the MMCs was insensitive to fibre content but for composites with fibre contents at or above the minimum of 16 vol% used for this work, the wear rate was about 18% of that of the unreinforced matrix. Fibre orientation had a minor effect on wear rate; the N orientation gave the lowest wear rate with the AP orientation slightly higher and the P orientation significantly higher.

The average coefficients of friction of the MMCs in N and AP orientations decreased linearly with increased wear rate and non-linearly with increased load, but the P orientation was insensitive to either variable.

It was concluded from these results and a metallographic examination that the mechanism of wear of MMCs was essentially oxidative wear of the matrix. The hard fibres modified this to slightly different degrees depending on their orientation relative to the wear surface and sliding direction.

Similar content being viewed by others

References

M. M. Schwartz, “Composite materials handbook” (McGraw-Hill, New York, 1984).

M. E. Buck,Materials and Design 8 (1987) 272.

B. C. Pai, P. K. Rohatgi andS. Venkatesh,Wear 30 (1974) 117.

B. P. Krishman, N. Raman, K. Narayanaswami andP. K. Rohatgi,ibid. 60 (1980) 205.

T. L. Ho andM. B. Peterson, in “Wear of Materials”, edited by N. A. Glasser and W. A. Glasser (ASME, New York, 1977) p. 70.

A. T. Alpas andD. Embury,Scripta Metall Mater. 24 (1990) 931.

Y. Sahin, Ph.D. Thesis, The University of Aston in Birmingham, 1994.

Y. Sahin andS. Murphy,Wear in press.

Z. Eliezer, C. H. Ramage andM. F. Amateau,Wear 49 (1978) 119.

M. F. Amateau, W. W. French andD. M. Goddard, in Proceedings of 1975 International Conference on Composite Materials, Vol 2 (TMS-AIME, New York, 1976) p. 623.

M. F. Amateau, R. H. Flowers andZ. Eliezer,Wear 54 (1979) 175.

M. F. Amateau, in “Mechanical behaviour of metal matrix composites”, edited by J. E. Hackaw and M. F. Amateau (TMS-AIME, Warrendale, PA, 1983) p. 213.

N. Saka andN. K. Szeto,Wear 157 (1992) 339.

J. Tao, C. Wang andM. Ying, in Wear of Materials 8th International Conference Orlando, edited by K. C. Ludema and R. G. Bayer (ASME, 1991) p. 601.

ASM Engineered Materials Reference Book, (ASME International, Metals Park, OH, 1989).

A. K. Dhingra andL. B. Gulbransen (eds), in Proceedings of Cast Reinforced Metal Composites, Chicago, (1988) p. 179.

H. Nayeb-Hashemi, J. T. Blucher andJ. Mirageas,Wear 150 (1991) 21.

H. Fukanaga andI. Sakai, in Proceedings of the 5th Conference on Production Engineering, Tokyo (1984) p. 673.

S. Das andB. K. Prasad,Wear 162–164 (1993) 64.

B. S. Tripathy andM. J. Fuery,ibid. 162–164 (1993) 385.

B. Viswanath, A. P. Verma andC. V. S. Kameswara Rao,Composites 21 (1990) 531.

P. K. Rohatgi andB. C. Pai,Wear 59 (1980) 323.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sahin, Y., Murphy, S. The effect of fibre orientation of the dry sliding wear of borsic-reinforced 2014 aluminium alloy. J Mater Sci 31, 5399–5407 (1996). https://doi.org/10.1007/BF01159309

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01159309