Conclusions

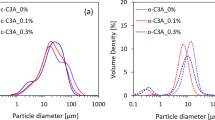

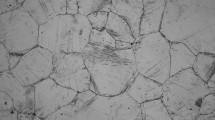

In the Al-Cu system a linear relationship between the end and starting porosities exists only at porosities exceeding 20%. At a smaller pore content the linearity is disturbed by the presence of an irreducible oxide phase on the aluminum particles. Decreasing the starting compact porosity results in greater growth in the first stage of sintering and smaller shrinkage in the second. The extent of the compact growth preceding the shrinkage may markedly exceed that due to copper and aluminum atom diffusion under conditions of uniform reaction of the liquid phase on all the surfaces of the particles. The anomalously large compact growth in the first stage of sintering is due to a negative regrouping of particles resulting from an uneven Kirkendall flow of material inside the particles, bringing about a change in their shape. The extent of shrinkage is not apparently linked with the structure forming during sintering, but depends on the starting porosity. Pores in a compact affect grain growth during sintering by inhibiting it.

Similar content being viewed by others

Literature cited

G. H. S. Price, C. J. Smithells, and C. V. Williams, “Sintered alloys. 1. Copper-nickel-tungsten alloys sintered with a liquid phase present,” J. Inst. Met.,62, No. 1, 239–254 (1938).

F. V. Lenel, “Sintering in the presence of a liquid phase,” Trans. AIME,175, 878–905 (1948).

H. S. Cannon and F. V. Lenel, “Some observations on the mechanism of liquid phase sintering,” in: Pulvermetallurgie, Transactions of the First Plansee Seminar “De Re Metallica” (1953), pp. 106–121.

J. E. Elliott, “Growth of sintered metal compacts,” Metallurgia,56, No. 1, 17–27 (1959).

V. I. Itin, A. P. Savitskii, K. V. Savitskii, et al., “The sintering of a P/M Cu-Al alloy,” Izv. Vyssh. Uchebn. Zaved., Fiz., No. 2, 139–144 (1965).

K. V. Savitskii, V. I. Itin, Yu. I. Kozlov, et al., “Role of contact pressure in the sintering of the Cu-Al system in the presence of a liquid phase,” Transactions of the Second Conference on Powder Metallurgy (Krakow, March 20–23, 1967), Krakow (1967), pp. 566–587.

K. V. Savitskii, Yu. I. Kozlov, V. I. Itin, et al., “The sintering of a P/M Ni-Al alloy,” Izv. Vyssh. Uchebn. Zaved., Fiz., No. 11, 139–141 (1967).

T. Krantz, “Effect of density and composition on the dimensional stability and strength of iron-copper alloys,” Int. J. Powder Metall.,5, No. 3, 35–43 (1969).

D. F. Berry, “Factors affecting the growth of 90/10 copper-tin mixes based on atomized powders,” Powder Metall.,15, No. 30, 247–266 (1972).

A. P. Savitskii, E. S. Kim, and L. S. Martsunova, “Compact shrinkage during liquidphase sintering,” Poroshk. Metall., No. 9, 9–13 (1980).

A. P. Savitskii, L. S. Martsunova, and M. A. Emel'yanova, “Compact porosity changes in iquid-phase sintering due to diffusional interaction between phases,” Poroshk. Metall., No. 1, 6–12 (1981).

A. P. Savitskii, M. A. Emel'yanova, and N. N. Burtsev, “Volume changes exhibited by Cu-Al compacts during liquid-phase sintering,” Poroshk. Metall., No. 5, 31–37 (1982).

A. P. Savitskii, N. N. Burtsev, and L. S. Martsunova, “Volume changes experienced by Al-Zn compacts during liquid-phase sintering,” Poroshk. Metall., No. 10, 11–16 (1982).

A. P. Savitskii and N. N. Burtsev, “Dilatometric investigations of the growth of Ti-Al compacts during liquid-phase sintering,” Poroshk. Metall., No. 3, 24–29 (1983).

A. P. Savitskii, M. A. Emel'yanova, and N. N. Burtsev, “Volume changes experienced by Cu-Sn compacts during liquid-phase sintering,” Poroshk. Metall., No. 12, 30–34 (1983).

A. P. Savitskii, G. N. Romanov, and L. S. Martsunova, “Deformation of aluminum-copper powder solids during liquid-phase sintering,” Poroshk. Metall., No. 8, 39–43 (1985).

A. P. Savitskii and G. N. Romanov, “Structure formation during the sintering of aluminum-copper alloys,” Poroshk. Metall., No. 3, 19–23 (1986).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 7(295), pp. 22–26, July, 1987.

Rights and permissions

About this article

Cite this article

Savitskii, A.P., Romanov, G.N. Effect of porosity on the volume changes experienced by Al-Cu compacts during liquid-phase sintering. Powder Metall Met Ceram 26, 532–536 (1987). https://doi.org/10.1007/BF01156551

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01156551