Abstract

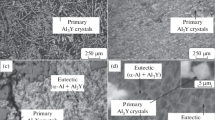

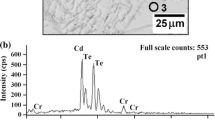

An Al-4.5% Cd alloy has been manufactured by melt spinning to produce a microstructure of 14–150 nm diameter faceted cadmium particles embedded in an aluminium matrix. The melting behaviour of the cadmium particles has been investigated by differential scanning calorimetry. The melting point of 20 and 14 nm diameter cadmium particles embedded are depressed by 7 and 9 K respectively, below the bulk equilibrium cadmium melting point, because of Gibbs-Thomson capillarity effects. The average solid cadmium particle/aluminium matrix interfacial energy is 27 mJ m−2 higher than the average liquid cadmium particle/aluminium matrix interfacial energy. No significant superheating is needed to nucleate cadmium particle melting.

Similar content being viewed by others

References

R. W. Cahn,Nature 323 (1986) 668.

Idem, ibid. 273 (1978) 491.

G. L. Allen, R. A. Bayles, W. W. Gile andW. A. Jesser,Thin Solid Films 144 (1986) 297.

P. R. Couchman andW. A. Jesser,Nature 269 (1977) 481.

V. P. Koverda,Phys. Metal. Metall. 51 (1981) 100.

S. J. Peppiatt andJ. R. Sambles,Proc. R. Soc. Lond. A345 (1975) 387.

S. J. Peppiatt,ibid. A345 (1975) 401.

V. G. Gryanzov, M. A. Gurskii, L. I. Trusov. andA. A. Aivazov,Sov. Phys. Solid State 24 (2) (1982) 297.

R. P. Berman andA. E. Curzon,Canad. J. Phys. 52 (1974) 923.

C. R. M. Wronski,Br. J. Appl. Phys. 18 (1967) 1731.

Ph. Buffat andJ-P. Borel,Phys. Rev. A 13 (1976) 2287.

G. L. Allen, W. W. Gile andW. A. Jesser,Acta Metall. 28 (1980) 1695.

H. Saka, Y. Nishikawa andT. Imura,Philos. Mag. A57 (1988) 895.

J. B. Boyce andN. Stutzmann,Phys. Rev. Lett. 54 (1985) 562.

C. J. Rossouw andS. E. Donnelly,ibid. 55 (1985) 2960.

D. L. Zhang andB. Cantor,Acta Metall. Mater. 39 (1991) 1595.

D. L. Zhang, K. Chattopadhyay andB. Cantor,J. Mater. Sci. 26 (1991) 1531.

T. B. Massalski, J. L. Murray, L. H. Mennett andH. Bakers, in “Binary Alloy Phase Diagram” (American Society for Metals, OH, 1986).

W. T. Kim, D. L. Zhang andB. Cantor,Met. Trans. 22A (1991) 2487.

“Metals Handbook”, 9th Edn (American Society for Metals, OH, 1989).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhang, D.L., Hutchinson, J.L. & Cantor, B. Melting behaviour of cadmium particles embedded in an aluminium matrix. J Mater Sci 29, 2147–2151 (1994). https://doi.org/10.1007/BF01154693

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01154693