Abstract

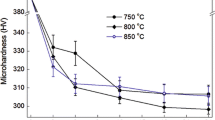

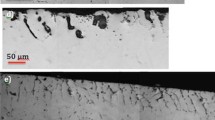

A standard regime of heat treatment has been developed for semifinished products of VT22 alloy manufactured by the conventional technology (casting + deformation). However, it gives a comparatively low level of crack resistance in the case of granular technology (hot isostatic pressing + deformation). In this connection it became necessary to refine the regime of heat treatment of the granulated VT22 alloy. The present work concerns the effect of different regimes of heat treatment on the size and shape of segregations of the ct-phase, investigated with the aim of improving the crack resistance characteristics of granulated VT22.

Similar content being viewed by others

References

V. V. Tetyukhin, A. N. Treshchevskii, V. N. Moiseev, et al., “Effect of hot deformation on the structure and properties of semifinished products from granules of VT22 alloy,” in:Metals Science and Treatment of Titanium and Nigh-Temperature Alloys, Collection of Works [in Russian], VILS, Moscow (1991), p. 229.

S. A. Saltykov,Stoichiometric Metallography [in Russian], Metallurgiya, Moscow (1976).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Moiseev, V.N., Sysoeva, N.V. & Ermolova, M.I. Heat treatment of granulated VT22 alloy. Met Sci Heat Treat 38, 42–45 (1996). https://doi.org/10.1007/BF01153872

Issue Date:

DOI: https://doi.org/10.1007/BF01153872