Abstract

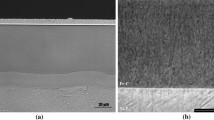

TiC x coatings were chemically vapour deposited in an industrial reactor on Fe-C substrates with carbon contents between 0.06 and 1.20 wt % C. Electron probe microanalyses showed that significant amounts of chromium and iron were present in the coatings and that chromium was also present in the substrate region adjacent to the coatings. By comparing calculated and measured lattice parameters (corrected for the internal stresses present) it became evident that the chromium was in solid solution in TiC x , whereas the iron was not. This was confirmed by micro Auger electron spectroscopy and X-ray diffraction phase analyses. The carbon to metal ratio,x, of the TiC x coatings decreased with increasing distance to the coating/substrate interface. The effect of iron on the X-ray diffraction line broadening and hardness of the coatings was large (in contrast with the effect of chromium) and increased with increasing distance to the coating/substrate interface because of a decreasing iron particle size. The TiC x crystallite size was small and constant throughout the thickness of the coatings. The chromium present in the substrate region adjacent to the TiC x coatings influenced the microstructure of the substrate by formation of iron, chromium-carbides and reduced the growth rate of the coatings.

Similar content being viewed by others

References

E. Broszeit andH. M. Gabriel,Z. Werkstofftechn. 11 (1980) 31.

W. S. Williams, in “Propriétés Thermodynamiques, Physiques et Structurales des Derives Semi-métalliques” (Editions du Centre National de la Recherche Scientifique, Paris, 1967) p. 181.

L. Ramqvist,Jernkont. Ann. 152 (1968) 517.

J.-L. Chermant, P. Delavignette andA. Deschanvers,J. Less-Common Metals 21 (1970) 89.

G. V. Samsonov, M. S. Kovalchenko, V. V. Dzwemlinskii andG. S. Upadyaya,Phys. Status Solidi (a) 1 (1970) 327.

S. Sarin,J. Appl. Phys. 39 (1968) 3305.

D. L. Kohlstedt, W. S. Williams andJ. B. Woodhouse,ibid. 41 (1970) 4476.

W. S. Williams,Phys. Rev. A 135 (1964) 505.

J. L. Murray, in “Binary Alloy Phase Diagrams”, Vol. 1, edited by T. B. Massalski et al. (American Society of Metals, Metals Park, Ohio, 1986) p. 593.

W. G. Sloof, R. Delhez, Th. H. de Keijser andE. J. Mittemeijer,J. Mater. Sci. 22 (1987) 1701.

M. Schwartz, in “Deposition Technologies for Films and Coating”, edited by R. F. Bunshah (Noyes, Park Ridge, New Jersey, 1982) p. 441.

P. P. J. Ramaekers, G. F. Bastin, W. B. Sloof, Th. H. de Keijser andR. Delhez,Vacuum 36 (1986) 19.

G. F. Bastin andH. J. M. Heijligers,X-ray Spect. 15 (1986) 135.

L. E. Davis, N. C. MacDonald, P. W. Palmberg, G. E. Riach andR. E. Weber, in “Handbook of Auger Electron Spectroscopy”, 2nd Edn (Physical Electronics Industries Inc., Eden Prairie, Minnesota, 1976).

R. DELHEZ, E. J. MITTEMEIJER, Th. H. de Keijser andH. C. F. Rozendaal,J. Phys. E 10 (1977) 784.

R. Delhez andE. J. Mittemeijer,J. Appl. Crystallogr. 8 (1975) 609.

C. R. Hubbard, H. E. Swanson andF. A. Mauer,ibid. 8 (1975) 45.

V. M. Hauk andE. Macherauch,Adv. X-ray Anal. 27 (1983) 81.

R. Chang andL. J. Graham,J. Appl. Phys. 37 (1966) 3778.

F. Bollenrath, V. Hauk andE. H. Müller,Z. Metallkde 58 (1967) 76.

W. G. Sloof, M. A. J. Somers, R. Delhez, Th. H. de Keijser andE. J. Mittemeijer, in “Residual Stresses in Science and Technology”, Vol. 1, edited by E. Macherauch and V. Hauck (Deutsche Gesellschaft für Metallkunde, Oberursel, 1987) p. 493.

R. Delhez, Th. H. de Keijser andE. J. Mittemeijer,Fresenius Z. Anal. Chem. 312 (1982) 1.

Th. H. de Keijser, J. I. Langford, E. J. Mittemeijer andA. B. P. Vogels,J. Appl. Crystallogr. 15 (1982) 308.

G. Rudolph andG. Schlamp,Metalloberfläche 23 (1970) 130.

P. P. J. Ramaekers, Thesis, University of Technology, Eindhoven (1985).

R. Lundberg, M. Waldström andB. Uhrens,CALPHAD 1 (1977) 159.

W. D. Forgeng andW. D. Forgeng Jr, in “Metals Handbook”, Vol. 3, edited by T. Lyman et al. (American Society for Metals, Metals Park, Ohio, 1973) p. 402.

P. P. J. Ramaekers, F. J. J. Van Loo andG. F. Bastin,Z. Metallkde 76 (1985) 245.

R. C. Sharma, G. R. Purdy andJ. S. Kirkaldy,Metal. Trans. 10A (1979) 1129.

J. R. Bradley, G. J. Shiflet andH. I. Aaronson, in “Proceedings of an International Conference on Solid → Solid Phase Transformations”, Pittsburg, Pennsylvania, 1981, edited by H. I. Aaronson et al. (The Metallurgical Society of AIME, New York, 1982) p. 819.

J. Kucera andK. Stransky,Mater. Sci. Engng 52 (1982) 1.

M. A. Krishtal, in “Diffusion Processes in Iron Alloys” (Keter Press, Jerusalem, 1970) p. 103.

F. Teyssandier, M. Ducarroir andC. Bernard,CALPHAD 8 (1984) 406.

E. K. Storms, in “The Refractory Carbides”, Vol. 2 (Academic, New York, 1967) p. 8.

J. Hauck,J. Less-Common Metals 105 (1985) 283.

F. Teyssandier, C. Bernard andM. Ducarroir, in Proceedings of the 6th European Conference on Chemical Vapour Deposition, Jerusalem, March-April, 1987, edited by R. Porat (Iscar, Hardmetal. Industrial Products, Nakaraya, Israel, 1987) p. 86.

G. Neumann, R. Kieffer andP. Ettmayer,Monatsh. Chem. 103 (1972) 1130.

J. P. Guha andD. Kolar,J. Less-Common Metals 31 (1973) 331.

Y. G. Zainulin, S. I. Alyamovsky andG. P. Shveikin,J. Phys. Chem. Solids 39 (1978) 29.

W. B. Pearson, in “A Handbook of Lattice Spacings and Structures of Metals and Alloys”, Vol. I (Pergamon, London, 1958) pp. 918, 961.

Idem, inibid.“ (1967) p. 1343.

E. Paulat, P. Lenk andG. Wieghardt,Härterei Tech. Mit. 39 (1984) 261.

D. J. Rowcliffe, in “Deformation of Ceramic Materials II”, Material Science Research, Vol. 18, edited by R. E. Tressler and R. C. Bradt (Plenum, New York, 1984) p. 49.

N. J. Grant, in “The Strengthening of Metals”, edited by D. Peckner (Chapman and Hall, London, 1964) p. 163.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sloof, W.G., Delhez, R., de Keijser, T.H. et al. Chemical constitution and microstructure of TiC x coatings chemically vapour deposited on Fe-C substrates; effects of iron and chromium. J Mater Sci 23, 1660–1672 (1988). https://doi.org/10.1007/BF01115705

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01115705