Summary

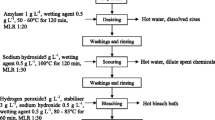

Wastewater from cotton yarn and fabric finishing was successfully treated in an upflow anaerobic filter at 35°C up to a COD loading of 1 Kgr COD/m3 · day; the COD removal varied from 50 to 90% and production of biogas was 0,2–0.4 L/g influent COD, having 70–80% CH4. At higher COD loading biogas production stopped although COD removal remainedca 50%.

Similar content being viewed by others

References

Environmental Pollution Control, Textile Processing Industry, EPA-625/778-002, Technology Transfer, October 1978.

Sidney G. Cooper, “The textile industry, environmental control and energy conservation”, Noyes Data Corporation, Park Ridge, N.J, U.S.A, 1978

“Emission control in the textile industry” Organization for Economic Cooperation and Development, Paris, 1981.

Nikos Athanasopoulos, “Cotton fabric desizing and Scouring wastewater treatment in upflow anaerobic filter”, Biotechnology Letters, 8,5,1986.

Standard Methods for the examination of water and Wastewater, 14th Ed., APHA Inc., Washington, D.C.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Athanasopoulos, N., Karadimitris, T. Cotton yarn and fabric finishing wastewater treatment in upflow anaerobic filter. Biotechnol Lett 10, 443–444 (1988). https://doi.org/10.1007/BF01087447

Issue Date:

DOI: https://doi.org/10.1007/BF01087447