Abstract

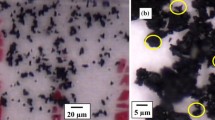

The microstructures of two polyester resin systems, with reactive liquid rubber additions incorporated, were investigated using electron microscopy. Fracture surface morphologies of failed fracture toughness specimens were examined using scanning electron microscopy. The fine structures of unfractured toughened resins were examined by imaging ultra thin sections in the transmission electron microscope. Three of the four rubber additives investigated produced, upon curing, a dispersion of second-phase rubber-rich particles in the polyester resin matrix. The fourth additive, which was more compatible with polyester than the other three, did not produce any detectable particle dispersion upon curing, even at relatively high concentrations. The fine structures of the particle distribution were found to be highly dependent upon both rubber and resin formulations. Rubber additions modified the mode of fracture observed in double torsion tests of polyester resins, from continuous crack propagation to “slip-stick”, and distinctive changes in fracture surface morphology were observed. In zones of crack arrest and slow stable crack growth, crack blunting occurred and highly deformed structures were seen on the fracture surface. In one system, this zone was split into two distinct regions, due to crack blunting and the initiation of new, sharp cracks. In zones of rapid crack growth, there was no evidence of crack blunting. The amount of crack blunting was highly dependent upon speed of testing.

Similar content being viewed by others

References

C. B. Bucknall, I. C. Drinkwater andW. E. Keast,Polymer 13 (1972) 115.

J. N. Sultan andF. J. McGarry, School of Engineering, M.I.T., Report R67-66 (1967).

J. N. Sultan, R. C. Liable andF. J. McGarry,Appl. Polymer. Symp. 6 (1971) 127.

E. H. Rowe andC. K. Riew,Plastics Engn. 31 (3) (1975) 45.

W. D. Bascom, R. L. Cottington, R. L. Jones andP. Peyser,J. Appl. Polymer. Sci. 19 (1975) 2545.

G. A. Crosbie andM. G. Phillips,J. Maler. Sci.in press.

C. K. Riew andR. W. Smith,J. Polymer. Sci. Al 9 (1971) 2739.

E. H. Rowe, Proceedings 34th Annual Technical Conference, S.P.I. RP/C Institute (1979) 23-B.

P. D. Tetlow, J. F. Mandell andF. J. McGarry,ibid., 23-F.

C. B. Bucknall, “Toughened Plastics” (Applied Science, London, 1977).

A. J. Kinloch andR. J. Young, “Fracture Behaviour of Polymers” (Applied Science, London, (1983).

D. C. Phillips, J. M. Scott andM. Jones,J. Mater. Sci. 13 (1978) 311.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Crosbie, G.A., Phillips, M.G. Toughening of polyester resins by rubber modification. J Mater Sci 20, 563–577 (1985). https://doi.org/10.1007/BF01026527

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01026527