Abstract

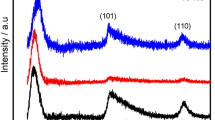

The hydrogen reduction of two non-stoichiometric samples of cobalt tungstate (one cobalt-rich, the other heavily tungsten-rich) has been studied over the temperature range 600 to 1100° C using thermogravimetry, X-ray diffraction analysis and scanning electron microscopy. The products are shown to be non-equilibrium at most reduction temperatures. In order to explain the experimentally observed X-ray diffraction data it is postulated that the reduction process occurs via the formation of an amorphous phase which contains cobalt, tungsten and oxygen. The amorphous phase becomes unstable at low oxygen potentials and precipitates either, or both, Co3W and Co7W6 depending upon the degree of cobalt enrichment of the amorphous phase. These are the only two cobalt-containing crystalline phases in the products of reduction and are not detected before at least 53% reduction has occurred. During the early stages of reduction either tungsten (for near stoichiometric, cobalt-rich oxide) or WO2 (for tungsten-rich oxide-CoWO4 plus WO3) are the only crystalline products of reduction.

Similar content being viewed by others

References

F. Gortsema andP. Kotval,Plansee. Pulvermet. 24 (1976) 254.

S. Takatsu,Powder Met. Int. 10 (1978) 13.

K. Ushijima,ibid. 11 (1979) 158.

T. D. Halliday, F. H. Hayes andF. R. Sale in “Industrial Uses of Thermochemical Data”, edited by T. I. Barry, Special Publication No. 34 (Chemical Society, London, 1980) p. 291.

G. J. French, PhD thesis, University of Manchester (1983).

J. Guerassimov, Proceedings 16th IUPAC International Congreess of Pure and Applied Chemistry, Paris (Butterworth, London, 1957) p. 227.

A. K. Basu andF. R. Sale,J. Mater. Sci. 12 (1977) 1115.

Idem, ibid. 13 (1978) 2703.

P. Walkden andF. R. Sale, “Proceedings 2nd European Symposium on Thermal Analysis (ESTA-2)”, Aberdeen (1981), edited by D. Dollimore (Heyden, London 1981) p. 531.

Idem, in “Electrical Contacts 1982”, Proceedings 28th Annual Holm Conference on Electrical Contacts, Illinois Institute of Technology, Chicago (1982) p. 101.

P. Bracconi andL. Dufour,Met. Trans. B 7B (1976) 321.

Idem, ibid. 7B (1976) 329.

T. Ekstrom andR. J. D. Tilley,J. Solid State Chem. 22 (1977) 331.

N. Schonberg,Acta Chem. Scand. 8 (1954) 630.

W. Morcom, W. Worrell, H. Sell andH. Kaplan,Met. Trans. 5 (1974) 155.

A. K. Basu andF. R. Sale, in “Modern Developments in Powder Metallurgy”, Vol. 9, edited by H. H. Hausner and P. V. Taubenblat, (Metal Powder Industries Federation and American Powder Metallurgy Institute, New Jersey, 1977), p. 171.

T. Wilken, C. Wert, J. Woodhouse andW. Morcom,ibid.in, p. 161.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

French, G.J., Sale, F.R. The hydrogen reduction of cobalt-tungsten mixed oxides. J Mater Sci 20, 1291–1300 (1985). https://doi.org/10.1007/BF01026325

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01026325