Abstract

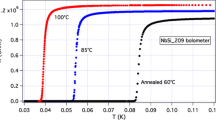

Techniques are described for producing improved infrared bolometers from doped germanium. Ion implantation and sputter metalization have been used to make ohmic electrical contacts to Ge:Ga chips. This method results in a high yield of small monolithic bolometers with very little lowfrequency noise. When one of these chips is used as the thermometric element of a composite bolometer, it must be bonded to a dielectric substrate. The thermal resistance of the conventional epoxy bond has been measured and found to be undesirably large. A procedure for soldering the chip to a metalized portion of the substrate is described which reduced this resistance. The contribution of the metal film absorber to the heat capacity of a composite bolometer has been measured. The heat capacity of a NiCr absorber at 1.3K can dominate the bolometer performance. A Bi absorber has significantly lower heat capacity. A low-temperature blackbody calibrator has been built to measure the optical responsivity of bolometers. A composite bolometer system with a throughput of ∼0.1 sr cm2 has been constructed using our new techniques. In negligible background, it has an optical NEP of\(3.6 \cdot 10^{ - 15} W/\sqrt {Hz}\) at 1.0K with a time constant of 20 ms. The noise in this bolometer is white above 2.5 Hz and is somewhat below the value predicted by thermodynamic equilibrium theory. It is in agreement with calculations based on a recent nonequilibrium theory.

Similar content being viewed by others

References

N. S. Nishioka, P. L. Richards, and D. P. Woody, Appl. Opt.17, 1562 (1978).

J. Clarke, G. I. Hoffer, P. L. Richards, and N-H. Yeh, J. Appl. Phys.48, 4865 (1977).

F. J. Low, J. Opt. Soc. Am.51, 1300 (1961).

F. J. Low, and A. R. Hoffman, Appl. Opt.2, 649 (1963).

E. E. Haller, M. R. Hueschen, and P. L. Richards, Appl. Phys. Lett.34, (8), 495 (1979).

P. M. Downey, Ph. D. thesis, Massachusetts Institute of Technology (1980) (unpublished).

Stycast 2850-FT, Emerson and Cuming, Inc., Canton, Mass. 02021.

R. E. Peterson, and A. C. Anderson, J. Low Temp. Phys.11, 639 (1973).

L. I. Maissel and R. Glang,Handbook of Thin Film Technology (McGraw Hill, New York, 1970) pp. 18-8–18-12.

T. K. Lakshamanan, Trans. 8th Nat. Vac. Symp. 1961, p. 868.

L. Holland,Vacuum Deposition of Thin Films (J. Wiley, New York, 1960, p. 155.

P. Huijer, W. T. Langendam, and J. A. Lely, Phillips Tech. Rev.24, 144 (1962).

G. Sidall and B. A. Probyn, Brit. J. Appl. Phys.12, 668 (1961).

R. Winston, J. Opt. Soc. Am.60, 245 (1970).

Nextel (TM) Velvet coating, 3M Co., St. Paul, MN 55101.

J. C. Mather, Appl. Opt.21, 1125 (1982).

H. Moseley (private communication).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lange, A.E., Kreysa, E., McBride, S.E. et al. Improved fabrication techniques for infrared bolometers. Int J Infrared Milli Waves 4, 689–706 (1983). https://doi.org/10.1007/BF01009690

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF01009690