Conclusions

-

1.

The error in measuring curvilinear surfaces is affected by two specific properties: the necessity of superposing the pointed tip on a given point of the surface and the variation of the angleγ between the measuring direction and the normal to the tested surface.

-

2.

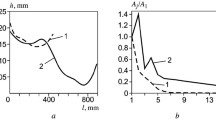

The root-mean-square subjective error in placing the measuring tip on the marked-out point of the surface increases from 0.004 to 0.13 mm with the angleγ rising from 0 to 47°.

-

3.

With a rising angleγ between the line of measurement and the normal to the tested surface the measurement error increases, so that at angles above 37° many instruments fail to give stable readings owing to the jamming of their measuring stems.

-

4.

For calculating contact deformations it is necessary to supplement the Hertz formula for the general case of a contact between two curvilinear surfaces by means of corrections for the angleγ and the moving force of the measuring tip along the surface.

-

5.

Variation of the measuring force in the range from 15·10−2 to 2 N virtually does not affect the measurement error of static ary measuring devices.

-

6.

A rise in the measuring force of portable measuring devices from 15·10−2 to 2 N increases the root-mean-square measurement error from 0.004 to 0.07 mm if the angleγ changes from 5 to 47°.

-

7.

Increasing the tip radius rt from 0.5 to 2.0 mm and setting it by means of the marking-out method raises the root-mean-square measurement error by 50–100%; the error increases by a factor of 2–2.5 for rt=2.5 mm.

-

8.

Raising the surface finish from Δ4 to Δ11-reduces the root-mean-square error on an average by a factor of two.

-

9.

If in measuring curvilinear surfaces the measuring tip is locked, the measured surface is lubricated, or the measuring system is provided with artificial vibration, the measurement error can be reduced on an average by a factor of 1.5 for small anglesγ and by a factor of 0.2–0.85 for larger angles.

Similar content being viewed by others

Literature cited

N. N. Markov et al., Errors and the Selection of Measuring Devices in Linear Measurements [in Russian], Mashinostroenie, Moscow (1967).

Encyclopedic Handbook [in Russian], Vol. 2, Mashinostroenie, Moscow (1948).

Additional information

Translated from Izmeritel'naya Tekhnika, No. 4, pp. 15–18, April, 1971.

Rights and permissions

About this article

Cite this article

Markov, N.N., Mel'nikov, V.P. Certain component errors of curvilinear surface measurements. Meas Tech 14, 533–536 (1971). https://doi.org/10.1007/BF00980152

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00980152