Conclusions

1. An equation has been derived for the strength during interlayer shear along reinforcing fibers of a composite material of unidirectional texture which allows calculation of this index as a function of composition of the material and state of the interphase boundary. Experimental confirmation of this equation has shown that the effectiveness of surface treatment of the reinforcing filler can be estimated by its use.

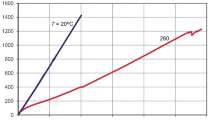

2. It has been shown that the strength during interlayer shear of an epoxy-phenol plastic can be increased by a factor of more than 3, and during bending by a factor of 1.3, as the result of treatment of high-modulus carbon fibers in nitric acid.

3. A correlation has been established between changes in electrical resistivity of the carbon fiber and the molecular component of adhesion to it of consolidated epoxy-phenol binder.

Similar content being viewed by others

Literature cited

V. I. Mimeault, "Carbon fiber composites: effect of fiber oxidation on composite behavior," Fibre Sci. Technol.,3, No. 4, 273–283 (1971).

J. C. Goan, "Method for improving graphite fibers for plastic reinforcement and products thereof," U.S. Patent 3634220 (1968).

M. Brie and C. Le Gressus, "Grafting of polymers on carbon fibers (grefface de polymers sur fibres carbon)." Fibre Sci. Technol.,6, No. 1, 47–54 (1973).

G. M. Gunyaev, N. G. Zhigun, P. G. Sorina, and V. A. Yakushin, "Resistance to shear of composites on a base of viscosized fibers," Mekh. Polim., No. 3, 492–501 (1973).

A. A. Berlin and V. E. Basin, Fundamentals of Adhesion of Polymers [in Russian], Moscow (1974).

G. M. Kerch and L. A. Irgen, "Influence of the structure of the polymeric matrix and area of its contact with filler on the stiffness of composite polyethylene," Mekh. Polim., No. 3, 387–391 (1974).

P. G. Babaevskii, V. M. Vinogradov, G. S. Golovkin, G. M. Gunyaev, L. P. Kobets, G. P. Mashinskaya, and V. N. Tyukaev, Plastics of Constructional Significance [in Russian], Moscow (1974).

L. P. Kobets, G. M. Gunyaev, and M. A. Kuznetsova, "Influence of treatment of the surface of carbon fibers on strength of the carboplastic during interlayer shear," Plast. Massy, No. 9, 69 (1976).

A. B. Kurkin, L. A. Pekal'n, A. S. Kotosonov, et al., "Change in electrical resistivity of a carbon fabric during storage in air," in: Constructional Materials on a Carbon Base [in Russian], Moscow (1974), pp. 210–214.

J. B. Donnet, E. Papierer, and H. Dauksch, "Surface modification of carbon fibres and their adhesion to epoxy resins," in: International Conference on Carbon Fibres, Their Place in Modern Technology, London (1974), Paper N9, pp. 1–11.

E. B. Trostyanskaya, L. P. Kobets, and G. M. Gunyaev, "Study of the elastic moduli of carbon fibers," Mekh. Polim., No. 5, 846–850 (1971).

T. Ya. Kintsis, A. B. Roze, and N. G. Zhigun (compiler), Methods of Statistical Tests of Reinforced Plastics [in Russian], Riga (1972).

Additional information

Moscow. Translated from Mekhanika Polimerov, No. 3, pp. 445–451, May–June, 1977.

Rights and permissions

About this article

Cite this article

Kobets, L.P., Gunyaev, G.M. Resistance to interlayer shear of plastics on a carbon filament base. Polymer Mechanics 13, 380–385 (1977). https://doi.org/10.1007/BF00859421

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00859421