Conclusions

-

1.

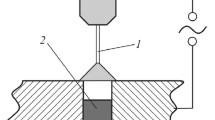

In the heat-affected zones adjacent to a welding seam obtained by argon-arc or electron-beam welding of alloy 36NKhTYu, intermittent decomposition does not occur during aging; this has a deleterious effect on the strength properties and the endurance in cyclic loading of specimens.

-

2.

To eliminate structural inhomogeneity and to improve the strength properties and the endurance of welded joints of alloy 36NKhTYu, it is indispensable, after welding, to carry out a second quenching at 930–1100°C.

Similar content being viewed by others

Literature cited

P. V. Syrovatchenko (ed.), in: Instrument Construction and Means of Automation (Handbook), Vol. 3, Book 2, Mashinostroenie, Moscow (1964), pp. 202–241.

V. F. Sukhovarov, Intermittent Phase Segregation in Alloys [in Russian], Nauka, Novosibirsk.

Additional information

Ust'-Kamenogorsk Pedagogic Institute. Institute of the Physics of Strength and Materials Science, Siberian Branch, Academy of Sciences of the USSR, Tomsk. MPO "Manometr.". Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 42–44, June, 1986.

Rights and permissions

About this article

Cite this article

Akhmetzhanov, B., Sukhovarov, V.F., Strokatov, R.D. et al. Heat treatment of welded joints of alloy 36NKhTYu. Met Sci Heat Treat 28, 439–442 (1986). https://doi.org/10.1007/BF00836894

Issue Date:

DOI: https://doi.org/10.1007/BF00836894