Conclusions

-

1.

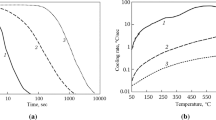

The stability of supercooled austenite in the investigated types of steel differs during accelerated cycles of temperature increase and annealing. 35KhNM steel was found to have the most stable residual austenite whereas that of 5KhV2S steel was least stable.

-

2.

Accelerated annealing with a cycle of temperature increase and decrease accompanies by supercooling to 220°C produces a more complete decomposition of supercooled austenite. The most complete decomposition of supercooled austenite is brought about by applying two cycles of temperature increase and decrease even when the holding time is of short duration. A single cycle of temperature increase and decrease with a prolonged holding time of 650°C enhances the stability of supercooled austenite (by stabilizing it).

-

3.

The selected standard piece is of major importance for the accuracy of the determination of residual austenite. Evidently, a most reliable control piece is obtained by subjecting the specimen to additional tempering.

-

4.

Extended holding periods (dozens of hours) at 200° to 300° and 640° to 660°C as commonly used in annealing forgings by temperature increase-decrease cycles are unjustified in that they adversely affect quality in that the stability of residual austenite is thereby increased.

Similar content being viewed by others

Bibliography

Ye. S. Tovpenets, A. G. Bobrov, A. A. Belanovskiy, “Interrupted Quenching of Large Forgings”,Metallurgizdat, 1955.

B. S. Natapov and N. A. Blagoveschenskiy, “Heat Treatment of Metals,”Metallurgizdat, 1955.

Ye. S. Tovpenets, F. I. Ivanov,MiTOM, No. 7, 1959.

Manual “Metallography and Heat Treatment,”Metallurgizdat, 1956.

P. V. Sklyuyev and V. G. Goryachko, “Metallography and Heat Treatment” Central Plant Laboratory, Urals Machinery Plant, 1950.

MiTOM, No. 4, supplement, 1960.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Tovpenets, Y.S., Ivanov, F.I. & Gontar', M.A. The effects of cooling techniques on the quantity of residual austenite during the forging of steel. Met Sci Heat Treat 4, 183–187 (1962). https://doi.org/10.1007/BF00819261

Issue Date:

DOI: https://doi.org/10.1007/BF00819261