Conclusions

-

1.

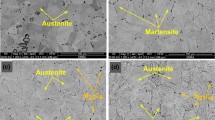

The reason for brittle failure of hot rolled EI652 alloy is slow cooling at 700–600°. During slow cooling there is decomposition of the solid solution and precipitation of an intermetallide phase of the type Ni3Al. The amount of phase precipitated depends on the length of time the metal remains within the danger on temperature range. Coupled with the stresses produced by work hardening and also the thermal stresses, the precipitation of this phase leads to the formation of cracks.

-

2.

To prevent the metal cracking, the sheets should be cooled in staggered fashion after rolling.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Boyarinova, A.P., Mel'kumov, I.N., Brusilovskiy, B.S. et al. Reasons for brittle failure in EI652 nickel-chrome-aluminum alloy. Met Sci Heat Treat 4, 141–143 (1962). https://doi.org/10.1007/BF00816366

Issue Date:

DOI: https://doi.org/10.1007/BF00816366