Conclusions

-

1.

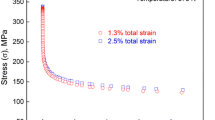

When plastic deformation accumulates in EI612 austenite steel, the relaxation is speeded up and in pearlitic 20Kh1M1F1 steel the resistance to relaxation increases continuously and the decrease in stresses is slowed down, almost to the point of total utilization of the ductility (0.90–0.95%).

-

2.

Failure when the stresses are relaxed or during combined relaxation-creep tests is due to exhaustion of the ductility. The degree of approach to failure under conditions of relaxation of smooth specimens can be described by the quantity ∈pl/δf, which may be used as a criterion for the damage. The ductility for any time is 1 − ∈pl,/δf.

-

3.

During relaxation the time prior to failure calculated by summation of the relative period over which the stresses act is equivalent to the time prior to failure in long-term rupture tests.

Similar content being viewed by others

References

Proc. Institute of Metal Physics, Issue 19, 1958.

V. I. Danilovskaya and others. Izvestiya AN SSSR, OTN, No. 5, 1955.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Liberman, L.Y. Relaxation strength of E1612 and 20Kh1M1F1 steels during tension and failure. Met Sci Heat Treat 4, 137–141 (1962). https://doi.org/10.1007/BF00816365

Issue Date:

DOI: https://doi.org/10.1007/BF00816365