Conclusions

-

1.

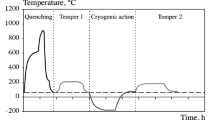

To prevent the formation of cracks in facing of hot rolling rolls of 9Kh2MF steel, it is necessary to furnace heat the rolls to 420°C and after facing to isothermally hold them at 550°C.

-

2.

As the result of facing an 8–10-mm-thick wear-resistant layer with a hardness of more than 550 HB and a structure of bainite with special carbides is created.

-

3.

The life of the rolls repaired by facing exceeds that of the hardened and tempered rolls by about 15%.

Similar content being viewed by others

Literature cited

M. A. Tylkin, Heat Treaters Handbook for Repair Work [in Russian], Metallurgiya, Moscow (1981).

S. Ya. Shekhter and A. Ya. Shvartser, Facing of Parts of Metallurgical Equipment [in Russian], Metallurgiya, Moscow (1981).

Ya. B. Fridman, The Mechanical Properties of Metals [in Russian], Vol. 1, Mashinostroenie, Moscow (1974), p. 278.

Additional information

Nizhnii Tagil Branch of Ural Polytechnic Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 5, pp. 13–14, May, 1986.

Rights and permissions

About this article

Cite this article

Siper, A.S., Tokareva, T.S., Lobanov, M.N. et al. Repair of universal beam mill rolls. Met Sci Heat Treat 28, 324–326 (1986). https://doi.org/10.1007/BF00814682

Issue Date:

DOI: https://doi.org/10.1007/BF00814682