Conclusions

-

1.

In consequence of recrystallyzation at 500°C a coarse crystalline structure appears in sheet aluminum after a preceding 7–15% deformation.

-

2.

Addition of 0.2% Ti totallly prevents the formation of coarse crystalline structure in aluminum annealed at 500°C even if previously strained up to 15%. At 0.1% Ti a coarse crystalline structure appears in aluminum strained by 15%, and at 0.05% Ti after 7% deformation.

-

3.

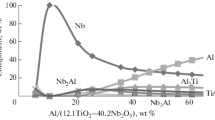

Addition of 0.05–0.5% Be, 0.05–0.2% Nb, or 0.1–5% Ga fails to produce any noticeable effect on the size of grain after a preceding 1.5–15% deformation.

-

4.

At 0.2% Re content a coarse crystalline structure is observable in aluminum only upon 15% deformation preceding the high-temperature heating, whereas smaller additions of rhenium (0.05–0.01%) fail to produce a positive influence.

Similar content being viewed by others

Rights and permissions

About this article

Cite this article

Belyayev, A.P., Gol'shteyn, R.M. The effect of minor additions of titanium, beryllium, gallium, rhenium and niobium on the aluminum grain size after heating and straining. Met Sci Heat Treat 3, 317–318 (1961). https://doi.org/10.1007/BF00810384

Issue Date:

DOI: https://doi.org/10.1007/BF00810384