Conclusions

-

1.

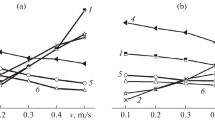

The strength and wear resistance of cermets based on zirconium carbide are determined by the conditions under which load is applied to them and also, in the case of any one system, such as ZrC-Nb, by the thickness of the metallic layers and, in the case of different systems, other things being equal, by the nature of the binding metal.

-

2.

Plots have been constructed showing that the intensity of wear of cermets belonging to one or different systems falls with increase in transverse rupture and compressive strengths.

-

3.

It has been established that the transverse rupture and compressive strengths of the cermets and their intensity of wear when exposed to a gas-abrasive stream under various conditions are determined by the difference in the degree of localization of valence electrons between the metallic binder and the carbideforming metal.

Similar content being viewed by others

Literature cited

I. V. Bogomol, An Investigation into the Preparation and Properties of Refractory Carbide Cermets with Refractory Metal Binders [in Russian], Summary of Candidate's Dissertation, IPM Akad. Nauk UkrSSR, Kiev (1973).

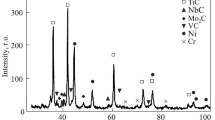

G. V. Samsonov, A. A. Dan'kin, et al., Poroshkovaya Met., No. 12 (1973).

M. Gensamer, E. B. Pearsall, and G. Smith, Trans. Am. Soc. Metals,28, 380 (1940).

M. Gensamer, E. B. Pearsall, et al., Trans. Am. Soc. Metals,30, 983 (1942).

A. S. Moroz, “The strengthening action of carbides in steel,” in: Symposium Commemorating the 70th Birthday of Academician A. F. Ioffe [in Russian], Izd-vo Akad. Nauk SSSR, Moscow (1950).

H. Unckel, Metall.,5, 146 (1951).

J. Gurland and P. Bardzil, J. Metals,7, No. 2, 311 (1955).

O. V. Stupushina and V. I. Likhtman, Dokl. Akad. Nauk SSSR,107, 252 (1956).

R. Felgar and J. Lubahn, ASTM Proc.,57, 770 (1957).

A. A. Dan'kin, V. I. Svetlopolyanskii, and V. D. Oreshkin, Hard-facing Alloys Based on Refractory Compounds [in Russian], VPI Im. A. S. Serafimovichs, Volgograd (1972), p. 27.

E. Orowan, Reports on Progress in Physics, Vol. 12, London (1959), p. 185.

J. R. Low, in: Structure and Properties of Metals [Russian translation], Metalloizdat, Moscow (1957).

G. V. Samsonov, I. F. Pryadko, and L. F. Pryadko, Configurational Model of Matter [in Russian], Naukova Dumka, Kiev (1971).

Author information

Authors and Affiliations

Additional information

Deceased.

Translated from Poroshkovaya Metallurgiya, No. 3(159), pp. 73–78, March, 1976.

Rights and permissions

About this article

Cite this article

Samsonov, G.V., Dan'kin, A.A., Markov, A.A. et al. Strength and gas-abrasive wear resistance of cermets based on zirconium carbide. Powder Metall Met Ceram 15, 220–224 (1976). https://doi.org/10.1007/BF00806532

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00806532