Conclusions

-

1.

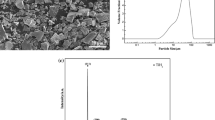

It was established that the shaping of titanium powder at very high pressures (6–7 tons/cm2), exceeding the yield stress of titanium, and subsequent vacuum sintering at 1100–1200°C is incapable of imparting a density of 100% to preforms. Because of the residual porosity (4–6%), the mechanical properties of such preforms are much lower than those of cast and worked titanium.

-

2.

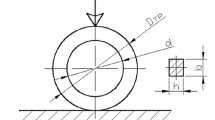

A study was made of the effect of forging, upsetting, and extrusion on the density of sintered titanium preforms. It is shown that a processing schedule consisting of cold shaping, sintering, and subsequent hot deformation enables a density of 100% to be attained.

-

3.

The mechanical properties of sintered specimens subjected to hot deformation were determined. It is demonstrated that the strength, ductility, and impact strength of such specimens approach those laid down by standard specifications for VT1-00 titanium alloy.

Similar content being viewed by others

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Rakovskii, V.S., Borzetsovskaya, K.M., Olenina, N.S. et al. Hot deformation of sintered titanium powder preforms. Powder Metall Met Ceram 12, 71–74 (1973). https://doi.org/10.1007/BF00803983

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00803983