Conclusions

-

1.

A study was made of the technological characteristics of a process for the preparation of ferromolybdenum alloy powder, in which mixtures of Fe3O4 and MoO3 oxides are subjected to ferritization and subsequent direct reduction.

-

2.

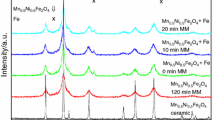

For compacted mixtures containing up to 1.5% MoO3, complete solid-phase ferritization is achieved. The optimum process parameters are a temperature of 900°C and a process duration of 6–9 h.

-

3.

To obtain a complex Fe3O4-MoO3-base oxide from mixtures with MoO3 contents of 1.5–10.5% or higher, another process is proposed, in which the ammonium chloride NH4Cl is added to the mixture to accelerate ferritization.

-

4.

The optimum process parameters have been determined for the ferritization of complex Fe3O4-MoO3 oxides, and some test results are reported. The new method may be applied to the preparation of ferrites, complex composite powders, and dispersion-hardening alloys.

Similar content being viewed by others

Literature cited

B. A. Borok and V. G. Teplenko, in: Researches in Powder Metallurgy (editor B. A. Borok), Consultants Bureau, New York (1966), p. 3.

E. M. Minaev and T. I. Mryakina, Poroshkovaya Met., No. 2, 1 (1968).

Oxydation des Métaux, Vol. 1, Procédés Fondamentaux, Paris (1962).

G. Tammann Z. Anorg, Allgem. Chem.,179, 21 (1925).

A. N. Zelikman and P. V. Belyaevskaya, Zh. Prikl. Khim.,27, 1151 (1954).

A. N. Zelikman and N. N. Gorovets, Zh. Obshch. Khim.,24, 1916 (1954).

S. S. Brenner, J. Electrochem. Soc.,102, 7 (1955).

A. N. Zelikman, Zh. Neorgan. Khim.,1, 2778 (1956).

Yu. D. Kozmanov, Zh. Fiz. Khim.,31, 1861 (1957).

Yu. D. Kozmanov and T. A. Ugol'nikov, Zh. Neorgan. Khim.,3 1267 (1958).

Yu. D. Kozmanov, Zh. Neorgan. Khim.,5 2048 (1960).

G. Tammann, Lehrbuch der Metallkunde, Berlin (1929).

I. Benard and B. Chaudron, Compt. Rend.,204, 766 (1937).

N. A. Filippov, Phase Analysis of Nonferrous Metal Ores and Ore Products [in Russian], Izd-vo Metallurgiya, Moscow (1964).

I. D. Radomysel'skii and S. G. Napara-Volgina, Poroshkovaya Met., No. 8, 12 (1965).

É. T. Denisenko, S. G. Napara-Volgina, and Yu. A. Fedorchenko, Poroshkovaya Met., No. 8, 28 (1967).

I. D. Radomysel'skii and S. G. Napara-Volgina, in: Powder Metallurgy and Metal Treatment [in Russian], Erevan (1967), p. 65.

I. D. Radomysel'skii and I. D. Martyukhin, in: Powder Metallurgy Materials and Components [in Russian], Erevan (1969), p. 62.

S. T. Rostovtsev and V. K. Simonov, Physicochemical Principles of Production [in Russian], Izd-vo AN USSR, Kiev (1961), p. 143.

N. V. Manukyan and A. A. Andreasyan, in: Powder Metallurgy Materials and Components [in Russian], Erevan (1969), p. 73.

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 3 (87), pp. 43–50, March, 1970.