Conclusions

-

1.

It was established that the densification of copper strip can be intensified by raising the sintering temperature to 1060°C.

-

2.

During the deformation of porous copper strip, the ductile-to-brittle transition occurs at small relative reductions, and the sooner the higher the starting strip porosity.

-

3.

The physicomechanical properties of densified and annealed strip from electrolytic and autoclave copper powders are comparable to those of copper strip of the usual ingot origin (σ t of not less than 21 kg/mm2,δ of not less than 30%, andρ of not more than 1.724 μΩ · cm).

Similar content being viewed by others

Literature cited

O. A. Katrus, R. L. Oganyan, and L. P. Savitskii, Poroshkovaya Met., No. 10 (1968).

W. D. Jones, Fundamental Principles of Powder Metallurgy, Edward Arnold, London (1960).

S. M. Solonin, Yu. M. Solonin, and V. V. Skorokhod, Poroshkovaya Met., No. 10 (1966).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 11(143), pp. 64–68, November, 1974.

Rights and permissions

About this article

Cite this article

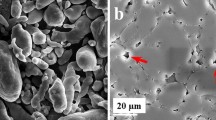

Katrus, O.A., Aleshina, A.V. & Perepelkin, A.V. Physicomechanical properties and microstructure of roll-compacted copper powder strip. Powder Metall Met Ceram 13, 917–921 (1974). https://doi.org/10.1007/BF00803198

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00803198