Conclusions

-

1.

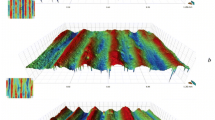

A study was made of the possibility of adding surface-active substances to a plasticizer (paraffin wax) and their effects on the extrusion characteristics of hard-alloy mixtures and quality of finished parts. It was established that the addition of 1% of a SAS to 5% of paraffin wax facilitates deformation through an adsorption effect, the extrusion pressure thus being lowered by 100 kg/cm2.

-

2.

Surface-active substances considerably simplify the preparation of a mixture for extrusion by eliminating the process of repeated mixing through a multiple-channel die.

Similar content being viewed by others

Literature cited

P. O. Gribovskii, Hot Casting of Ceramic Parts [in Russian], Gosénergoizdat, Moscow-Leningrad (1961).

S. S. Voyutskii, A Course of Colloid Chemistry [in Russian], Izd-vo Khimiya, Moscow (1964).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 2 (86), pp. 11–13, February, 1970.

Rights and permissions

About this article

Cite this article

Plyushch, G.V., Slezko, A.I. Use of surface-active substances in the extrusion of hard alloys. Powder Metall Met Ceram 9, 99–101 (1970). https://doi.org/10.1007/BF00802140

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00802140