Conclusions

-

1.

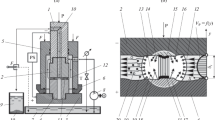

A study was made of the effects of the main technological parameters and of the geometry of the atomizing nozzle on the effectiveness of the atomization process in the preparation of metal powders.

-

2.

It was established that the energy expended on disintegration alone is negligible, amounting to a few per cent of the total energy required for conducting the process.

-

3.

It was found that the efficiency of the process cannot be appreciably raised by varying technological and design parameters.

Similar content being viewed by others

Literature cited

O. S. Nichiporenko, Poroshkovaya Met., No. 11, 1 (1969).

Yu. V. Ivanov, Principles of Calculation and Design of Burners [in Russian], Gostoptekhizdat, Moscow (1963).

O. S. Nichiporenko and Yu. I. Naida, Poroshkovaya Met., No. 4 (1968).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 2 (86), pp. 1–5, February, 1970.

Rights and permissions

About this article

Cite this article

Nichiporenko, O.S. Effectiveness of the atomization process for the manufacture of metal powders. Powder Metall Met Ceram 9, 91–94 (1970). https://doi.org/10.1007/BF00802138

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00802138