Conclusions

-

1.

Controlling rolling (ter=800±20°C) of steels type 20–22K makes it possible to increase short-time (σu, σ0.2) and long-time (σ 10000450 ) strength: by 5–15% and 10–15%, respectively, for steel without additives, and by 20–30% and 30–40% for steel doped with vanadium or niobium, with ductility maintained at the level δ≥25% and a1≥70 J/cm2.

-

2.

Controlled rolling with controlled subsequent cooling enhances the level of short-time strength of carbon steel by a factor of 1.3–1.5, and of doped steel by a factor of 2.3.5 while the characteristics of ductility are maintained (δ≥14–18%, a1≥70 J/cm2). The characteristics of long-time strength of steel from ordinary production without additives are 10–20% poorer, and of doped steel 30–40% better than of steel after controlled rolling.

-

3.

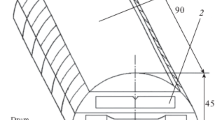

We suggested a refined algorithm for calculating the cooling regimes of sheet in TMT and from the results structural phase diagrams of carbon boiler steel 20K and steel type 20K doped with vanadium (0.06%) or niobium (0.05%) were plotted. According to the diagrams we can evaluate the distribution of structures over the section of sheet with different thickness (h=5–40 mm), both with cooling in air and in accelerated cooling (cooling in water for 2.5 to 20 sec).

Similar content being viewed by others

Literature cited

P. Bufalini and H. Potremoli, Revue de Metallurgie—CIT,80, No. 1, 67–76 (1983).

M. Kazahynsky, in: Eighth PTD Conference Proceedings (1988), pp. 79–87.

T. Yukhimosi, Sumitomo Kindzoku,32, No. 3, 288–307 (1980).

V. E. Dobrovol'skii, I. I. Trunin, M. V. Demin, and N. V. Levitskii, "Method of evaluating the time to rupture of steel in creep," Teploénergetika, No. 8, 55–56 (1987).

Yu. I. Matrosov, Doped Cold-Resistant Steels for Overland Pipelines with Large Diameter Used after Controlled Rolling [in Russian], Author's abstract of doctoral thesis, Chermetinformatsiya, Moscow (1989).

M. V. Bobylev, D. V. Kisin, and A. V. Kudrya, "Choice of heat-treatment conditions of forgings under laboratory conditions," Izv. Vyssh. Uchebn. Zaved., No. 9, 105 (1990).

A. A. Popov and A. E. Popova, Isothermal and Thermokinetic Diagrams of Decomposition of Supercooled Austenite [in Russian], Mashgiz, Moscow (1961), p. 432.

L. Meyer, M.-E. Buhler, and F. Heisterkamp, Thyssenforschung,3, No. 1-2, 8–43 (1971).

Additional information

I. P. Bardin Central Research Institute of Ferrous Metallurgy. Translated from Metallovedenie i Termicheskaya Obrabotka Metalloved, No. 10, pp. 17–21, October, 1991.

Rights and permissions

About this article

Cite this article

Bobylev, M.V., Kireev, V.B. & Koreshkova, A.M. Properties of doped boiler steel after controlled rolling. Met Sci Heat Treat 33, 742–747 (1991). https://doi.org/10.1007/BF00800693

Issue Date:

DOI: https://doi.org/10.1007/BF00800693