Conclusions

-

1.

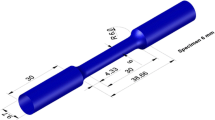

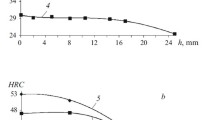

The method of planned experiments was used to obtain a mathematical model describing the effect of temperature and carburizing time and quenching temperature on the probability of fracture of samples of steel KhVG in static tests.

-

2.

The quenching temperature was the largest effect on the probability of failure of carburized samples of steel KhVG.

-

3.

The optimal quenching temperature is 780–810° after carburizing at 840–900° for 6 h.

Similar content being viewed by others

Literature cited

V. M. Pereverzev et al., in: Improving the Wear Resistance of Connecting Rods in Diesel Tractor Engines by Carburizing [in Russian], Tr. TsNITA, No. 63, Leningrad (1974), p. 55.

Additional information

Kursk Polytechnic Institute. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 1, pp. 16–18, January, 1979.

Rights and permissions

About this article

Cite this article

Pereverzev, V.M., Kolmykov, V.I. Effect of carburizing and quenching on the tendency to fracture of steel KhVG. Met Sci Heat Treat 21, 21–23 (1979). https://doi.org/10.1007/BF00800391

Issue Date:

DOI: https://doi.org/10.1007/BF00800391