Conclusions

-

1.

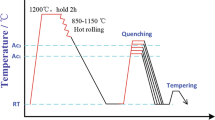

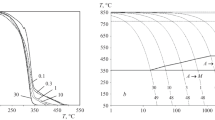

The mechanical and service properties of structural steels can be substantially improved by isothermal quenching; as a result, lower bainite forms, and, in addition, a certain amount of metastable residual austenite (up to 20%) is retained in the structure; then, in tests, this austenite is gradually transformed into martensite.

-

2.

The largest amount of residual austenite is found in steels after brief holding (up to 15 min) with all isothermal temperatures, and when the holding time is extended, the amount decreases. In subsequent deformation the degree of stability of residual austenite increases with rising temperature of isothermal holding.

-

3.

The best combination of strength, ductile properties, and impact toughness is attained only when the amount of residual austenite and the degree of its stability are optimal for the kind of steel involved.

-

4.

Industrial tests of pneumatic hammers heat-treated in the corrected regime showed that their operational life was doubled.

Similar content being viewed by others

Literature cited

I. N. Bogachev and R. I. Mints, Cavitation Failure of Iron-Carbon Alloys [in Russian], GNTI Mashinostroitel'noi Literatury, Sverdlovsk (1959).

L. S. Malinov and T. D. Éismondt, "Strengthening of unstable austenitic Cr−Mn−N steels," Izv. Akad. Nauk SSSR, Met., No. 12, 113–120 (1969).

L. S. Malinov and A. P. Cheilyakh, "The effect of the stability of austenite on the mechanical properties of Fe−Cr−Mn base austenitic-martensitic steels," Paper deposited at the Institute Chermetinformatsiya, No. 912, Dnepropetrovsk, February 15, 1980, Mariupol'skii Metallurgicheskii Institut, Mariupol (1979), pp. 2–9.

V. S. Popov, N. N. Brykov, and N. S. Dmitrichenko, Wear Resistance of Molds for the Production of Refractories [in Russian], Metallurgiya, Moscow (1971).

L. S. Malinov and A. P. Cheilyakh, "The use of steel Kh12M for making cornmill hammers," Tekhnologiya i Organizatsiya Proizvodstva, No. 2, 31–32 (1982).

A. G. Rakhshtadt, Spring Steels and Alloys [in Russian], Metallurgiya, Moscow (1982).

A. Yu. Kaletin and V. M. Schastlivtsev, "The effect of residual austenite on the properties of steel after isothermal quenching," in: Problems of the Failure of Metals [in Russian], Metallurgiya, Moscow (1980), pp. 139–143.

A. P. Cheilyakh, L. S. Malinov, and K. N. Sokolov, "The correlation between mechanical properties and the development of martensitic transformation in tests of Fe−Cr−Mn steels," Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 4, 86–92 (1986).

B. G. Serebrennikova and M. E. Blanter, "The nature of thermal stabilization of austenite," Metalloved. Term. Obrab. Met., No. 2, 7–9 (1972).

Additional information

Mariupol Metallurgical Institute. Production Association "Azovmash." Translated from Metalovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 12–15, December, 1989.

Rights and permissions

About this article

Cite this article

Malinov, L.S., Cheilyakh, A.P., Kharlanova, E.Y. et al. Effect of isothermal quenching on the amount and stability of residual austenite and on the properties of structural steels. Met Sci Heat Treat 31, 872–876 (1989). https://doi.org/10.1007/BF00798227

Issue Date:

DOI: https://doi.org/10.1007/BF00798227