Conclusions

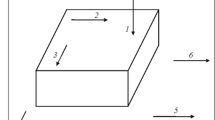

At room temperature the strength of ZhS6 nickel alloy produced by the granule metallurgy method is 1.5 times higher and its plasticity 3–4 times higher than those of the same alloy produced by the standard casting process. The P/M alloy remains superior in strength to the cast alloy up to temperatures of the order of 750–800°C, above which the strength characteristics of the P/M alloy fall below the level of properties of the cast material. The deformation of the P/M alloy varies in character depending on testing temperature, and three types of specimen fracture are possible: brittle fracture without waist formation in the temperature range 20–700°C, fracture with waist formation at 700–1000°C, and plastic deformation along the whole specimen length above 1000°C. At temperatures of 1000–1150°C the P/M alloy exhibits superplasticity: At low rates of deformation its elongation attains several hundred percent when the load is about 0.1σ0.2. The elongation of the specimen, load applied, and type of stress-strain diagram depend to a large extent on the rate of deformation: As the latter is decreased, δe sharply grows and the load diminishes.

Similar content being viewed by others

Literature cited

A. A. Bochvar, Superplasticity of Metals and Alloys [in Russian], Moscow (1969).

A. F. Belov, M. S. Gil'dengorn, O. Kh. Fatkullin, and G. S. Krykina, “The superplasticity of P/M nickelbase alloys,” Izv. Akad. Nauk SSSR, Met., No. 2, 149–152 (1974).

T. D. Kelso, “The advent of superplastic alloys,” Manuf. Eng. Management,64, No. 5, 55–56 (1970).

S. H. Reichman, B. W. Castledine, and J. W. Smythe, “Powder metal nickel superalloys may be formed superplastically,” Soc. Automotive Eng. J.,78, No. 4, 59–61 (1970).

V. P. Konoplenko and D. K. Vinogradov, “A machine for the elevated-temperature tensile testing of microspecimens in a vacuum,” Zavod. Lab., No. 6, 106–108 (1959).

V. P. Konoplenko, V. A. Zarubin, L. L. Artyukhina, and V. I. Eliseev, “Modified IRM-0.2 MIFI machine for the tensile testing of microspecimens,” Zavod. Lab., No. 1, 106 (1972).

M. Macclintock and A. Argon, Deformation and Fracture of Materials [Russian translation], Mir, Moscow (1970), pp. 163–167, 210–214.

D. McLean, Mechanical Properties of Metals [Russian translation], Metallurgiya, Moscow (1965), pp. 217–248.

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 1(205), pp. 76–80, January, 1980.

Rights and permissions

About this article

Cite this article

Konoplenko, V.P., Artyukhina, L.L., Tubyshkin, Y.A. et al. Dependence of the mechanical properties of a P/M nickel alloy on deformation temperature and rate. Powder Metall Met Ceram 19, 57–60 (1980). https://doi.org/10.1007/BF00798167

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00798167