Conclusions

-

1.

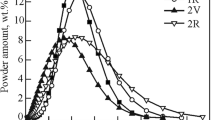

A study was made of the technological properties of Kh18N15 stainless steel powders having different particle size distributions and particle shapes.

-

2.

It is demonstrated that, as the amount of a medium and a fine fraction rises, the apparent density and the flowability increase, while the degree of powder compression during compaction decreases. The apparent density and the flowability of powder mixtures may diminish when the particles of the fine fraction do not arrange themselves in the interparticle pores of the main, coarse fraction.

Similar content being viewed by others

Literature cited

I. M. Fedorehenko and R. A. Andrievskii, Principles of Powder Metallurgy [in Russian] (1961).

B. A. Borok, R. P. Shchegoleva, et al., Poroshkovaya Met., No. 3 (1964).

G. V. Samsonov and S. Ya. Plotkin, Manufacture of Iron Powder [in Russian], Metallurgizdat, Moscow (1957).

A. A. Bochvar, Metal Science [in Russian], Metallurgizdat (1956).

G. F. Tikhonov, A. V. Sivov, and L. A. Pyryalov, Tr. Gor'kovsk. Politekhn. Inst. im. A. A. Zhdanova,19, No. 1 (1963).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 1 (97), pp. 1–4, January, 1971.

Rights and permissions

About this article

Cite this article

Tikhonov, G.F., Sorokin, V.K. Effect of particle size distribution on technological properties of stainless steel powder. Powder Metall Met Ceram 10, 1–3 (1971). https://doi.org/10.1007/BF00798036

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00798036