Conclusions

-

1.

It has been shown that Relit coatings of high particle microhardness can in principle be produced by the technique of atmospheric spray-deposition.

-

2.

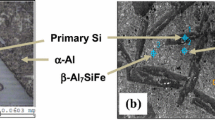

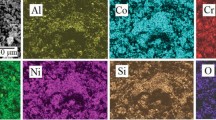

Spray-deposited Relit consists of disk-shaped and globular particles having a complex microstructure. Their open porosity is 7–11%, while their density is 13.5–14.0 g/cm3.

-

3.

The microhardness of spray-deposited Relit is strongly affected by the powder particle size. When Relit powder of 45–150-μ particle size is used, the resulting microhardness lies in the range 650–2400 kg/mm2.

-

4.

The bonds between the particles in spray-deposited Relit are comparatively weak. The bend strength of the material is 5–10 kg/mm2, while its Vickers hardness is 100–250 kg/mm2.

-

5.

To produce wear-resistant surfaces capable of withstanding high specific loads, spray-deposited coatings must be subjected to some additional treatment such as solder consolidation or sintering.

Similar content being viewed by others

Literature cited

B. M. Zakharov and M. T. Trofimov, Transactions of the Third Seminar on Oxidation-Resistant Coatings [in Russian], Nauka, Moscow (1968).

V. I. Veprintsev and E. I. Yanvarev, in: Hard Alloys [in Russian], Sb. Tr. VNIITS, No. 8, Metallurgiya (1969).

V. I. Veprintsev and Yu. A. Otradinskii, in: Hard Alloys [in Russian], Sb. Tr. VNITTS, No. 8, Metallurgiya (1969).

P. V. Gladkii, E. F. Perepletchikov, and N. T. Frumin, Avtomat. Svarka, No. 9 (1968).

S. Yu. Sharivker and M. I. Olievskii, Poroshkovaya Met., No. 12 (1968).

P. Schwarzkopf and R. Kieffer, Refractory Hard Metals, Macmillan, New York (1967)

G. D. Nikiforov and V. I. Privezentsev, Fiz. i Khim. Obrabotki Mater., No. 1 (1969).

V. V. Kudinov, N. N. Hykalin, and M. Kh. Shorshorov, Fiz. i Khim. Obrabotki Mater., No. 4 (1968).

Yu. A. Galkin, V. V. Kudinov, and M. Kh. Shorshorov, Fiz, i Khim. Obrabotki Mater., No. 1 (1969).

Author information

Authors and Affiliations

Additional information

A cast tungsten carbide hard alloy — Translator's note.

Translated from Poroshkovaya Metallurgiya, No. 6 (102), pp. 85–90, June, 1971.

Rights and permissions

About this article

Cite this article

Bobrov, G.V., Privezentsev, V.I., Nikiforov, G.D. et al. Structure and properties of spray - Deposited relit alloy. Powder Metall Met Ceram 10, 496–500 (1971). https://doi.org/10.1007/BF00797389

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00797389