Conclusions

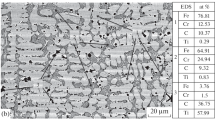

Eutectic chromium-carbide composites show promise as materials for coatings applied by the plasma spray-deposition technique. Use of composite powdered mixtures of chromium and carbides enables coatings to be obtained having phase compositions identical with those of cast alloys. The plasma spray-deposited Cr-TiC, Cr-TaC, and Cr-NbC coatings investigated were found to be superior in wear resistance to sintered alloys of the same compositions and to both cast and plasma spray-deposited chromium. The chromium-carbide composite coatings retained their good wear resistance up to 1000°C. The best results were obtained with Cr-11% TiC and Cr-27% TaC materials. Coatings of this type would appear to be particularly suitable for service under conditions of high-temperature wear in an oxidizing atmosphere, such as are encountered in metallurgical and power generating installations and gas turbine engines.

Similar content being viewed by others

Literature cited

V. I. Trefilov, Yu. V. Mil'man, and S. A. Firstov, Physical Basis of the Strength of Refractory Metals [in Russian], Naukova Dumka, Kiev (1975).

L. P. Ceuna and D. A. Kolar, “The systems TiC-Cr and ZrC-Cr,” J. Less-Common Met.,31, No. 3, 337–343 (1973).

A. K. Shurin and G. P. Dmitrieva, “Constitution diagrams of the Cr-ZrC and Cr-HfC systems,” Metallofizika,31, 105–109 (1974).

T. F. Fedorov, N. M. Popova, L. Y. Gorshkova, R. V. Skolozdra, and Yu. B. Kuz'ma, “Phase equilibria in the system vanadium-chromium-carbon, niobium-chromium-carbon, and tantalum-chromium-carbon,” Poroshk. Metall., No. 3, 42–48 (1968).

G. V. Samsonov, G. Sh. Upadkhaya, and V. S. Neshpor, Physical Materials Science of Carbides [in Russian], Nauka Dumka, Kiev (1974).

E. Foster and E. Price, “Cast refractory alloy,” U.S. Pat. No. 3554737, Jan. 12, 1971.

F. Lembey and E. Thomson, “Monocarbide reinforced eutectic alloys and articles,” U. S., Pat. No. 3528808, Sept. 15, 1970.

E. M. Dunlevey and J. F. Wallace, “The effect of thermal cycling on the structure and properties of a Co, Cr, Ni-TaC directionally solidified eutectic alloy,” Metall. Trans.,5, No. 6, 1351–1356 (1974).

O. V. Bakun, “Investigation of wear-resistant chromium alloys,” in: Cast Wear-Resistant Materials [in Russian], Kiev (1975), pp. 42–46.

Yu. G. Tkachenko, R. A. Alfintseva, I. N. Gorbatov, and V. M. Litvin, “High-temperature wear of chromium-base alloys,” Poroshk. Metall., No. 12, 61–65 (1978).

V. I. Yushkov, Yu. S. Borisov, and S. M. Gershenzon, “Relationship between necessary thermal power of a plasma jet and the thermophysical characteristic of material being spray-deposited,” Fiz. Khim. Obrab. Mater., No. 4, 20–22 (1975).

E. K. Storms, The Refractory Carbides, Academic Press, New York-London (1967).

N. N. Korneev, S. B. Pevzner, E. N. Razuvaev, and V. B. Emel'yanov, Plastic Working of Refractory Metals and Alloys [in Russian], Metallurgiya, Moscow (1975).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 11(227), pp. 74–80, November, 1981.

Rights and permissions

About this article

Cite this article

Trefilov, V.I., Borisov, Y.S., Alfintseva, R.A. et al. Structure and properties of chromium-carbide composite materials and coatings. Powder Metall Met Ceram 20, 805–810 (1981). https://doi.org/10.1007/BF00796483

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00796483