Conclusions

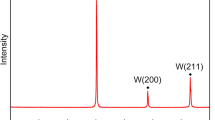

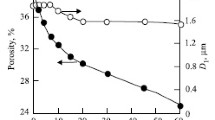

It has been established that the fall in the activity of a tungsten powder produced by reduction at 950°C and annealed, before pressing, at a temperature of 1700°C or higher is due not to growth of its particles during the annealing but to a decrease in the internal porosity of the particles and their agglomeration and spheroidization. With single-fraction as-reduced and annealed powders their is a correlation between the maximum size of pore channel constructions in a compact and the letter's sintering behavior. Prior heat treatment of tungsten powders produced by reduction at an end temperature of 700°C exerts a nonmonotonic influence on their sintering activity. Shorttime (τ=30 sec) sintering of compacts from such tungsten powders has been found to result in the formation of a new porous structure, with enlarged maximum pore channel constrictions, responsible for their sintering behavior. A correlation has been discovered between the volume shrinkage of compacts and the maximum size of constrictions in the enlarged capillaries.

Similar content being viewed by others

Literature cited

I. M. Fedorchenko and R. A. Andrievskii, “Mechanism of sintering of single-component system,” Poroshk. Metall., No. 1, 9–14 (1961).

Ya. E. Geguzin, The Physics of Sintering [in Russian], Nauka, Moscow (1967).

V. A. Ivensen, Kinetics of Metal Powder Densification during Sintering [in Russian], Metallurgiya, Moscow (1971).

M. Yu. Bal'shin, Scientific Principles of Powder and Fiber Metallurgy [in Russian], Metallurgiya, Moscow (1972).

V. V. Skorokhod, V. V. Panichkina, Yu. M. Solonin, and I. V. Uvarova, Fine Refractory Metal Powders [in Russian], Naukova Dumka, Kiev (1979).

L. A. Vermenko, O. I. Get'man, and S. P. Rakitin, “Effect of Powder particle size on the structure and properties of magnetic powder ceramics,” Elektron. Tekh., Mater., No. 11, 25–32 (1980).

A. S. Berkman and I. G. Mel'nikov, Porous Permeable Ceramics [in Russian], Stroiizdat, Leningrad (1969).

V. V. Skorokhod, Rheological Principles of Sintering Theory [in Russian], Naukova Dumka, Kiev (1972).

L. A. Vermenko, O. I. Konovalyuk, and S. M. Solonin, “Effect of pore size growth during the active sintering of tungsten powders,” in: Fine Crystalline Powders in Materials Science [in Russian], Kiev (1980), pp. 126–128.

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 11(227), pp. 25–31, November, 1981.

Rights and permissions

About this article

Cite this article

Vermenko, L.A., Get'man, O.I., Rakitin, S.P. et al. Effect of heat treatment of the densification behavior of porous bodies from fine tungsten powders during sintering. Powder Metall Met Ceram 20, 766–771 (1981). https://doi.org/10.1007/BF00796474

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00796474