Conclusions

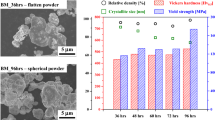

Chemical metallization of nonmetallic and metallic powders improves the homogeneity of powder mixtures, increases the uniformity of distribution of a deposited metal within a mixture, and substantially raises the level of properties of sintered parts. Chemical metallization of powders is the most effective at low concentrations of the metal being reduced (⇏3%).

Similar content being viewed by others

Literature cited

V. G. Mel'nikov, T. F. Yudina, and R. A. Yumatova, “The alloying of sintered antifrictional materials by the chemical reduction of one of their components,” Poroshk. Metall., No. 12, 46–48 (1975).

V. G. Mel'nikov, A. M. Kozlovskii, E. A. Nogovitsin, and S. V. Zvonov, “Electrodeless tinning of copper powders,” Poroshk. Metall., No. 2, 1–3 (1979).

T. F. Yudina, “Investigation of the process of chemical copper plating of very finely divided powdered materials,” Author's Abstract of Candidate's Dissertation, Ivanovo (1970).

T. F. Yudina, G. A. Uvarova, V. G. Mel'nikov, et al., “Sensitizing and activating solution for nonmetallic materials,” Inventor's Certificate No. 916589, Byull Izobret., No. 12 (1982).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 4(256), pp. 44–47, April, 1984.

Rights and permissions

About this article

Cite this article

Yumatova, R.A., Mel'nikov, V.G. Effect of method of introduction of an alloying metal on the properties of mixtures and sintered materials. Powder Metall Met Ceram 23, 290–292 (1984). https://doi.org/10.1007/BF00796390

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00796390