Conclusions

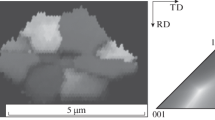

The sintering of a Cr3C2-15% Ni hard metal is accompanied by increases in the area, perimeter, and diameter of sections of its carbide grains; the mean value of dimensionless form factor of the grains remains unchanged during the process. At the same time sintering intensifies the size and shape heterogeneity of the carbide grains: It increases the amount of both large carbide grains and grains of elongated shape with small value of form factor, which are characterized by low strength.

Similar content being viewed by others

Literature cited

V. I. Tret'yakov, Principles of Metallurgy and Production Technology of Sintered Hard Metals [in Russian], Metallurgiya, Moscow (1976).

G. I. Reest and B. Young, “A study of the factors controlling grain size in sintered hard metal,” Powder Metall.,14, No. 27, 185–198 (1971).

I. N. Chaporova and K. S. Chernyavskii, Structure of Sintered Hard Metals [in Russian], Metallurgiya, Moscow (1975).

B. Čech, “The problem of carbide grain growth in the manufacture of hard carbide alloys by powder metallurgy,” Hutnické Listy,13, No. 2, 113–123 (1958).

L. É. Val'dma and Yu. Yu. Pirso, “Some relationships between processing factors and the properties of chromium carbide hard metals.” Transactions of the Fifth Powder Metallurgy Conference in GDR, Vol. 2, Dresden (1973), pp. 1–14.

B. Čech, “Beitrag zur Frage des Wachstums von Kristallkörnern bei der Erzeugung gesinterter Karbid,” Neue Huette, No. 5, 300–302 (1958).

Yu. Yu. Pirso, L. É. Val'dma, and Yu. K. Mazing, “Thermal fatigue resistance of sintered chromium carbide alloys,” Tr. Tallinsk. Politekh, Inst., No. 381, 39–45 (1975).

L. E. Val'dma and Yu. Yu. Pirso, “Character of wear of sintered chromium carbide alloys in an abrasive particle stream,” Poroshk. Metall, No. 5, 84–88 (1975).

V. V. Grigor'eva and V. N. Klimenko, Chromium Carbide Alloys [in Russian], Izd. Akad. Nauk Ukr. SSR, Kiev (1961).

E. M. Ionkina and I. A. Bel'ko, “Investigation of the structure of a sintered chromium carbide alloy by stereological analysis,” in: Powder Metallurgy [in Russian], Vysheishaya Shkola, Minsk (1979), pp. 14–19.

K. S. Chernyavskii, Stereology in Metal Science [in Russian], Metallurgiya, Moscow (1977).

S. A. Saltykov, Stereometric Metallography [in Russian], Metallurgiya, Moscow (1970).

E. M. Ionkina, G. A. Mironovich, L. V. Akimova, et al., “Quantitative changes in the structure of a chromium carbide hard metal induced by inoculation,” in: Powder Metallurgy [in Russian], Vysheishaya Shkola, Minsk (1981), pp. 70–76.

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 4(256), pp. 12–17, April, 1984.

Rights and permissions

About this article

Cite this article

Ionkina, E.M., Anishchik, T.A., Reznik, L.B. et al. Variation of the size and shape of the carbide grains of a chromium carbide-nickel hard metal during sintering. Powder Metall Met Ceram 23, 267–272 (1984). https://doi.org/10.1007/BF00796384

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00796384