Conclusions

-

1.

The application of load to a reinforced composite in the elastic region causes some fibers to rupture. A criterion of damage sustained by a reinforced composite may be provided by the number of fiber breaks.

-

2.

The strenth of a reinforced composite is strongly affected by the uniformity of fiber distribution over the matrix cross section. An irregular arrangement of fibers increases the number of rupture acts in the elastic region of loading.

-

3.

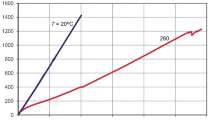

Raising the temperature at which a reinforced composite is tested increases the length over which load is transferred from the matrix to the fibers and decreases the number of fiber breaks.

Similar content being viewed by others

Literature cited

M. G. Lozinskii, High-Temperature Metallography [in Russian], Moscow (1961).

V. S. Ivanova, I. M. Kop'ev, and L. M. Ustinov, Annual Review of Progress in Science and Engineering Metallography and Heat Treatment Issue [in Russian], Moscow (1965).

W. H. Sutton and J. Chorné, in: Fibrous Composite Materials [Russian translation], Mir, Moscow (1967).

A. Kelly and G. J. Davies, Met. Rev.,10, No. 37, 1 (1965).

D. M. Karpinos and L. I. Tuchinskii, Poroshkovaya Met., No. 11 (1968).

É. S. Umanskii, Poroshkovaya Met., No. 1 (1969).

Author information

Authors and Affiliations

Additional information

Translated from Poroshkovaya Metallurgiya, No. 4 (100), pp. 69–73, April, 1971.

Rights and permissions

About this article

Cite this article

Karpinos, D.M., Bespyatyi, V.A. Rupture of nickel-base reinforced composites. Part II. Powder Metall Met Ceram 10, 310–314 (1971). https://doi.org/10.1007/BF00795989

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF00795989